Solar, Utilities & Environment

Common challenges

Development of inexpensive solar cells and photovoltaic materials with efficient solar-to-electric energy conversion is one of the most important challenges we face to offset electricity obtained from burning fossil fuels. Established technologies are available in modules with 15 – 20% efficiencies, however they are still too expensive to manufacture. To overcome this obstacle, researchers are looking to optimize existing crystalline silicon or thin film (e.g., copper indium gallium selenide (CIGS), cadmium telluride and amorphous silicon) solar cell architectures as well as explore new designs based on inorganic quantum dots and organic thin films. To advance solar-to-electric energy conversion, it is necessary to understand and control the dynamics of hot electron and hole relaxation, cooling, charge transport, and interfacial charge transfer of the photogenerated carriers. Useful information to characterize these state of the art photovoltaics includes:

- Measure material composition and uniformity

- Determine grain boundary losses and activity across a photovoltaic device

- Defect analysis

- Understand what reduces the current you can collect

- Quantify contamination levels

- Analyze chemical phases

INNOVATIVE TECHNIQUES

To adequately characterize and understand materials that affect your product’s energy output, you must first ensure each specimen is of the highest quality to resolve the material interface and properly controlled so you manipulate it, when necessary, under environmental stimuli. Once prepared, several techniques are available to better understand the relationship between microstructure, defects and the optical properties of materials.

|

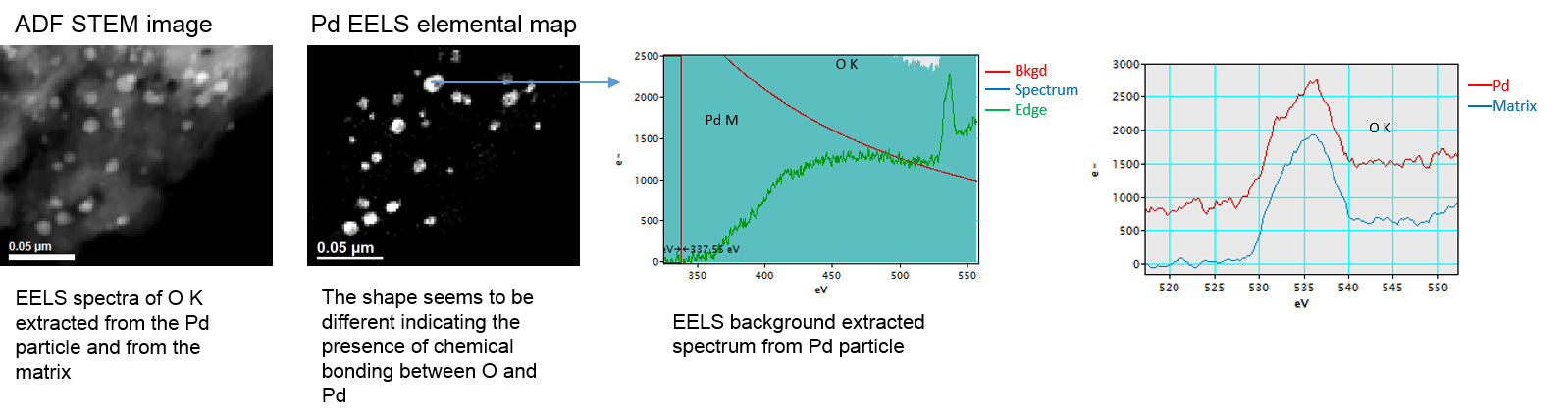

Electron energy loss spectroscopy (EELS)

Atomic resolution chemical and compositional analysis. |

Family of imaging techniques to enhance, map and quantify elements and chemicals in an image with nanometer resolution.

|

|

Systematic method to generate a spatially resolved distribution of electron energy loss spectroscopy (EELS) data.

|

Award winning, high resolution imaging tools help you to understand material growth, devices ultrastructure and failures.

|

|

Real-time observation of growth processes, chemical reactions and oxidation, irradiation effects, mechanical, magnetic, and ferroelectric properties.

|

Specimen preparation

High-performance tools to cut, etch, polish and freeze samples for your unique SEM, TEM or STEM application.

|

|

Useful to elucidate elemental or chemical characterization of a sample.

|

Helps you examine crystallographic orientation or texture of materials.

|

Visit batteries and energy storage or geosciences for related applications.

Enabling results

Analyze chemical phases

When you correlate particles within an image with EELS analyses, the results deliver insight into the chemical interaction of metals within catalytic systems for oil refineries.