Advantages:

Built upon a groundbreaking optical design, Monarc® dramatically boosts sensitivity and spectral resolution, empowering the most complete cathodoluminescence (CL) analysis to date with unique wavelength- and angle-resolved capabilities. This true next-generation CL detector now provides brand-new insights into the most demanding applications in nanophotonics, optoelectronics, and geosciences.

Fastest time to the best data

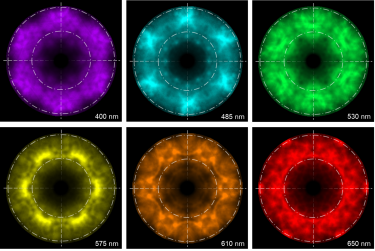

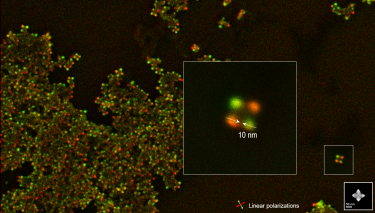

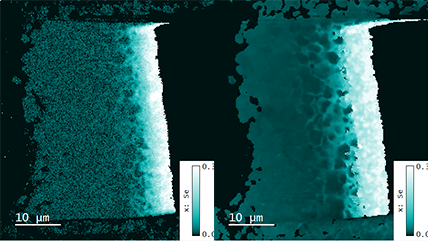

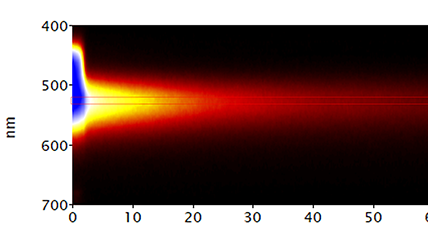

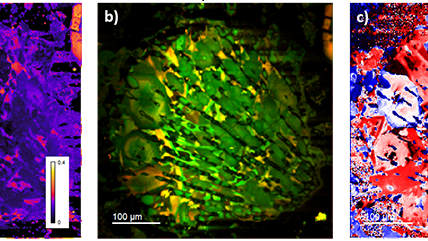

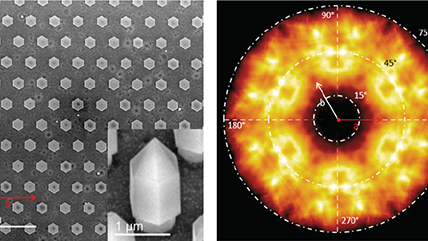

- Acquire CL data with unmatched spatial (<10 nm), angular (1°), and wavelength (0.1 nm) resolutions

- Simultaneously capture angle- and wavelength-resolved CL data

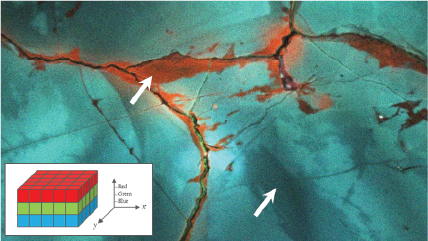

- Collect hyperspectral data up to 30 times faster than other CL detectors

Easy operation for all users

- Guarantee optimal results with fully automated alignment and recipe-driven operation

- Permanently aligned optics deliver reproducible results across the short- and long-term

- Utilize the largest field of view to increase the data throughput and simplify user workflows

Most accurate correlation with other signals

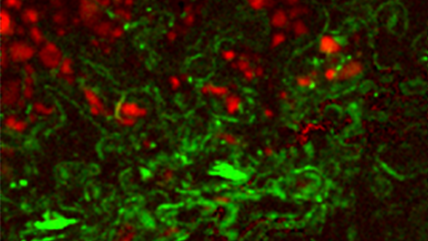

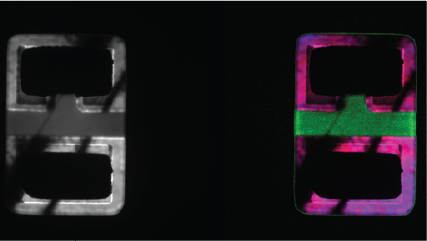

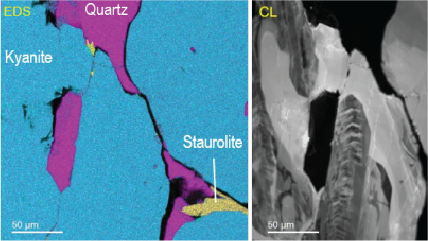

- Detect multiple signals simultaneously for correlated imaging of physical properties and composition with CL data

- No compromises – Make full use of the in-lens SEM detectors during CL measurements

Unique Capabilities

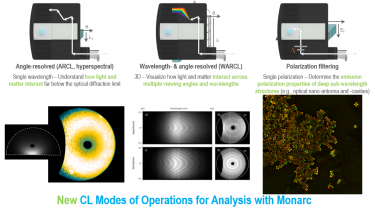

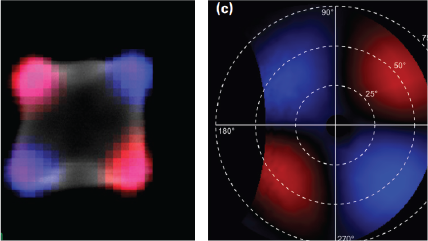

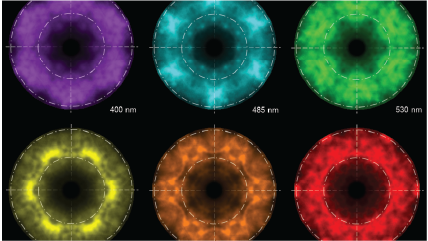

- Angle-resolved (ARCL): Understand how light and matter interact far below the optical diffraction limit – Provides a 400x larger field of view than other CL detectors with virtually no loss in resolution (patent pending)

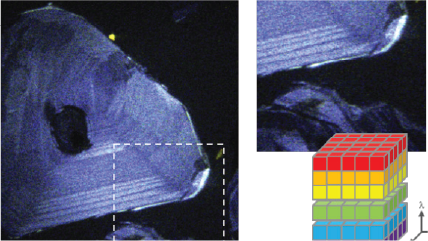

- Wavelength- and angle-resolved (WARCL): Visualize how light and matter interact across multiple viewing angles and wavelengths at full resolution – What was impossible or highly impractical, is now routine with Monarc’s unique optical design

- Polarization filtering: Determine the emission polarization properties of deep sub-wavelength structures like optical nanoantenna, nano-cavities, and photonic crystals

Models 450, 450.P

Datasheet

Applications

Related products

ChromaCL2 iBSED Detector

Cooling Stages

DigiScan™ 3 System

DigitalMicrograph® Software

STEMPack™ Spectrum Imaging