Advantages:

- Vacuum load-lock and liquid nitrogen cold stage to provide rapid workflows on beam sensitive samples

- Real-time observation of the polishing process including an optical microscope with digital imaging; images can be stored and analyzed with DigitalMicrograph® software from Gatan

- Repeatable results from recipes and operation of the Ilion® II via a 10" color touch screen interface

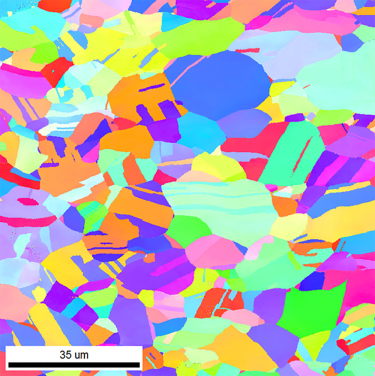

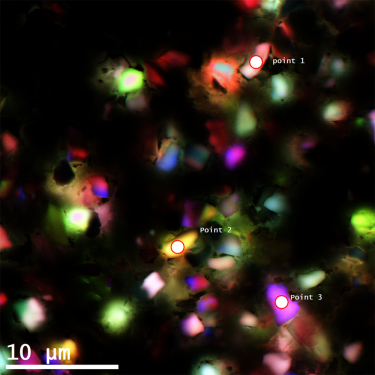

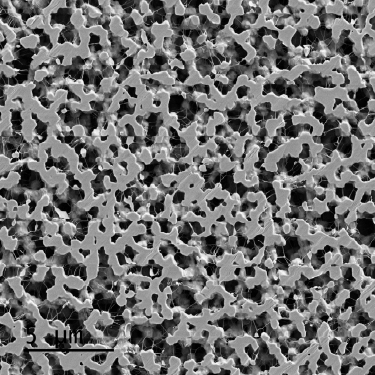

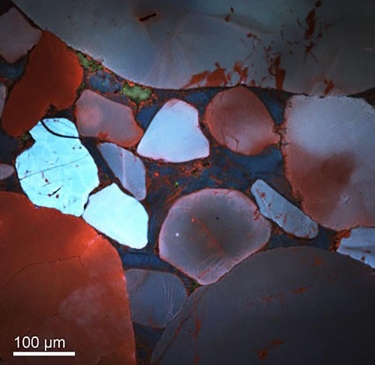

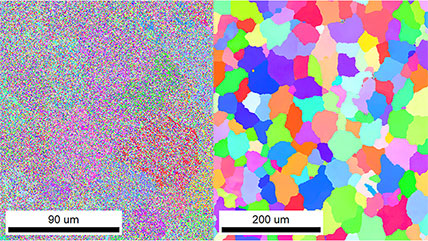

- Damage-free surfaces for analytical techniques, such as cathodoluminescence and EBSD, where the signal is generated near the surface

Journal of Alloys and Compounds

2022

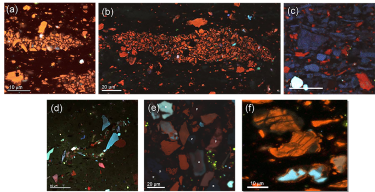

Materials

2022

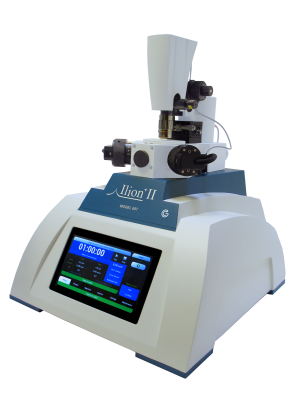

Model 697

Datasheet

Applications

|

EBSD sample preparation on Al/Mg bulk material using the Gatan Ilion II System |

Protocols

Cleaning guns and cold cathode gauge

Related products

Monarc CL Detector

ChromaCL2 System

DigitalMicrograph® Software

Murano Heating Stage

PECS II