What is serial block-face imaging?

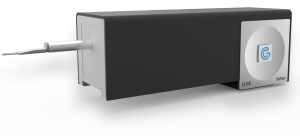

Serial block-face scanning electron microscopy (SBEM, SBSEM, and SBFSEM) is a way to reproducibly obtain high resolution 3D images from a sample. This method is particularly good at imaging large fields-of-view in X,Y,Z at nanometer resolution. SBEM typically relies on an in-situ ultramicrotome to be installed inside a scanning electron microscope (SEM). The SEM will collect an image of the block face, then the ultramicrotome will cut the sample to expose the next layer to be imaged, in steps as small as 15 nm.

Advantages of SBEM

| Capability | Advantage |

|---|---|

| Examines structure across orders of magnitude in scale | Maintains level of detail throughout a large dataset |

| Allows high throughput with no intervention | Useful to speed up sample analysis and reduce human error |

| Elucidates the context of observed ultrastructure | Enables you to gain more comprehensive results from one sample |

| Controls all aspects of the sectioning and acquisition process | Allows complete flexibility to optimize for a given sample |

| Eliminates section loss, damage and distortion | Avoids prohibitive processing to correct damage and distortion |

Uses

| Neuroscience | Cell biology | Material science | Other |

|---|---|---|---|

|

|

|

|

Neuroscience

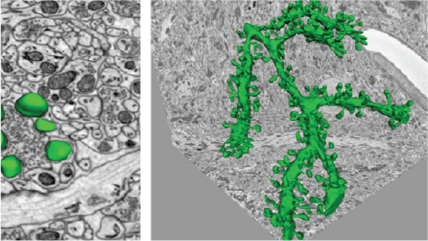

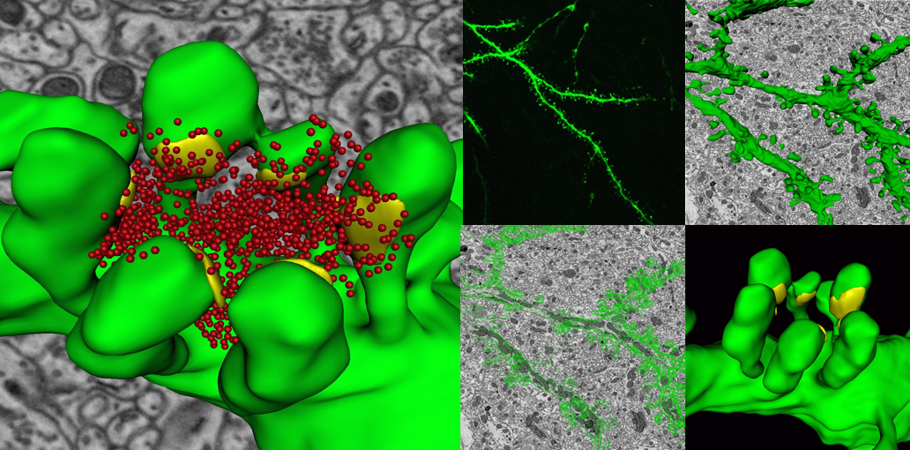

A 3D reconstruction of a dendrite from a 15,625 μm³ (25 x 25 x 25 μm) volumetric data set containing 500 serial images of mouse cerebellum generated by the 3View® system. Dendrite structure (green), buttons (yellow), and vesicles (red). Inset images, clockwise from top left: Confocal image of a dendrite; wire frame traces rendered into a volumetric model; ultra-resolution dendritic spine model with synapses; and image showing wire frame traces.

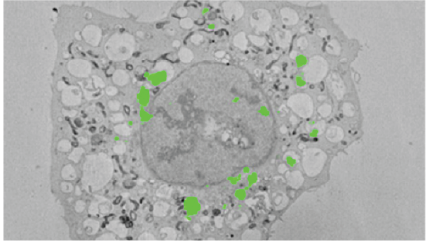

Cell biology: Complement confocal

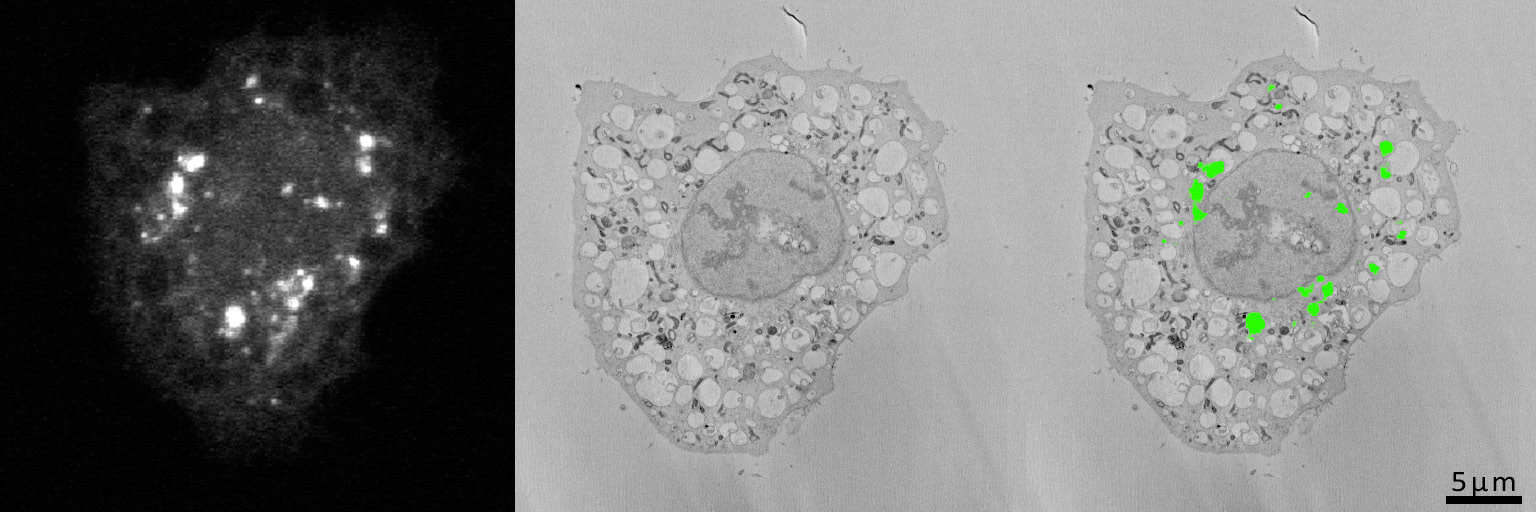

Image of HeLa cells, stably expressing LC-GFP grown on gridded glass bottom coverslips dishes, starved for 2 h in serum-free medium and cells of interest identified by confocal microscopy. The cells were then processed in situ for electron microscopy and the coverslips dissolved from the epoxy resin with hydrofluoric acid. The cells were again identified in the resin block and in subsequent serial images generated by the 3View system.

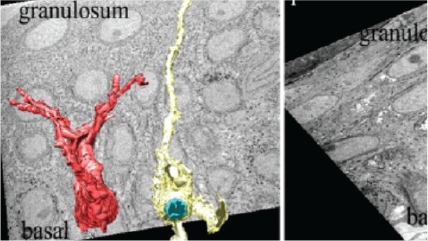

Cell biology: Developmental

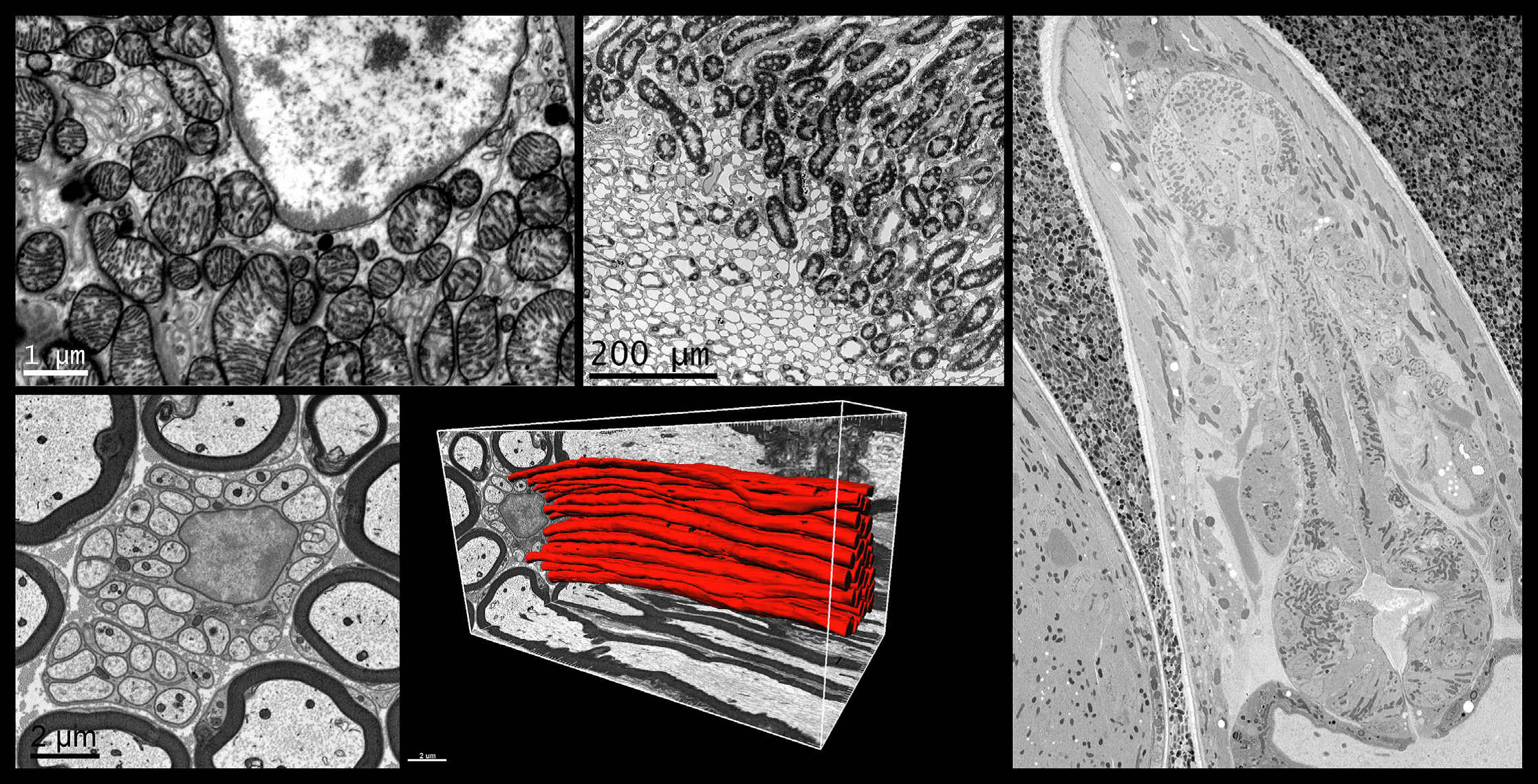

Top left: High resolution, mouse kidney, 8192 x 8192 pixel image acquired with 1.5 nm pixels. Top middle: Large field-of-view, mouse kidney, 8192 x 8192 pixel image acquired with 80 nm pixels. Right: C. elegans prepared by high pressure freezing; 4096 x 4096 pixel image acquired with 25 nm pixels. Sample courtesy of Kent McDonald, University of California, Berkeley. Bottom left: Mouse sciatic nerve, 2048 x 2048 pixel image acquired with 5 nm pixels. Bottom middle: 3D visualization of mouse sciatic nerve axons.

Material science

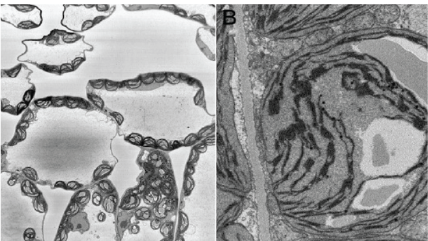

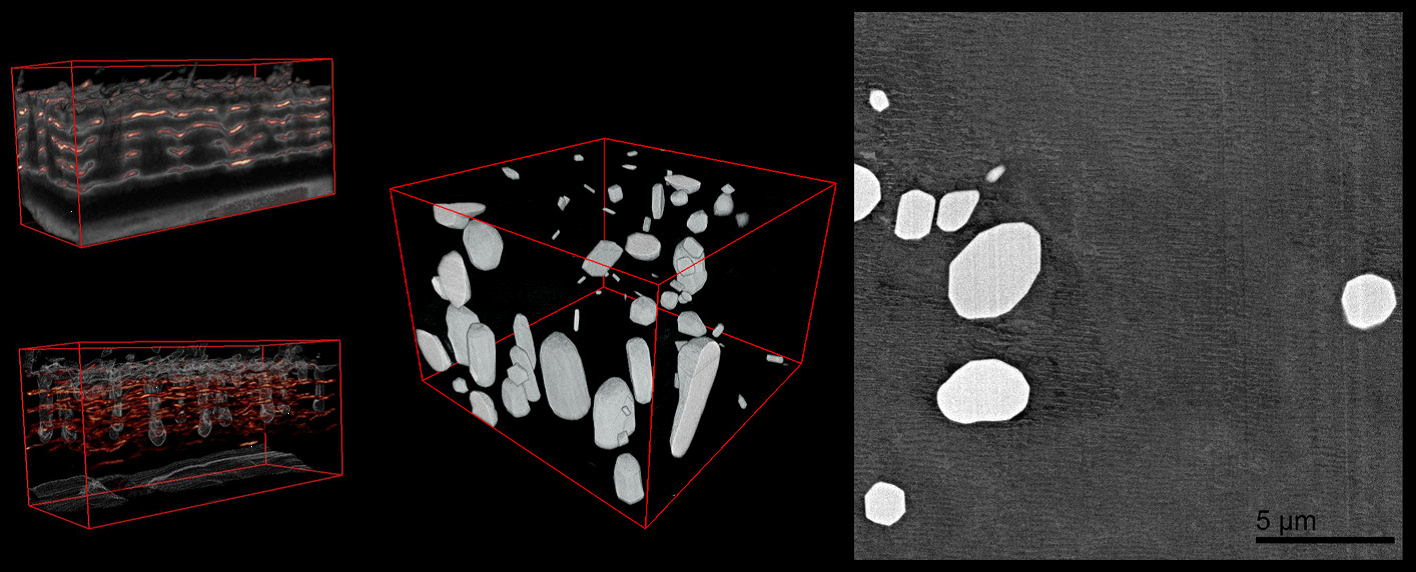

Upper and lower left: Images of anodized coating on aluminum surface generated by 3View system. Middle: 3D visualization of aluminum alloy with manganese particles generated by 3View system. 3D dataset contains one thousand 1024 x 1024 serial images with a pixel size of 15 nm and a cut thickness of 15 nm. 3D model created in DigitalMicrograph® using the 3D Visualization plugin.

Workflow for serial block-face imaging

3View system quick start guide

|

|

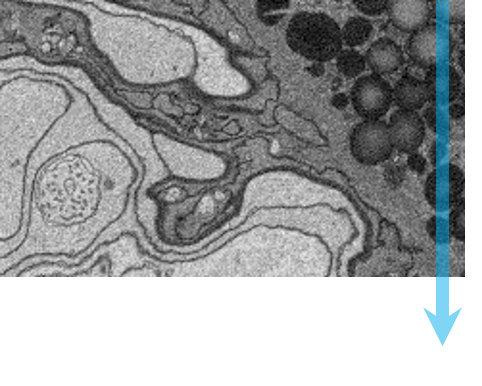

Step 1: Specimen preparation A typical biological specimen is fixed, stained with a contrasting agent and embedded in resin for stability. |

|

Step 2: Mount and transfer to SEM The specimen is trimmed to size, mounted to an aluminum pin, and optionally given a thin gold sputter coating. The specimen pin is put in the 3View system, the diamond knife is brought into contact, the door closed and evacuated. |

|

Step 3: Optimize imaging The user selects suitable beam conditions, similar to conditions for standard SEM, but also considering effects in the Z direction. Magnification, pixel count, and dwell time are chosen such that the image has the desired resolution, field-of-view, and acquisition time. |

|

Step 4: Automated imaging Sequential images are acquired with beam conditions of the user’s choice. Before each image, the knife removes a layer from the surface of the specimen. |

|

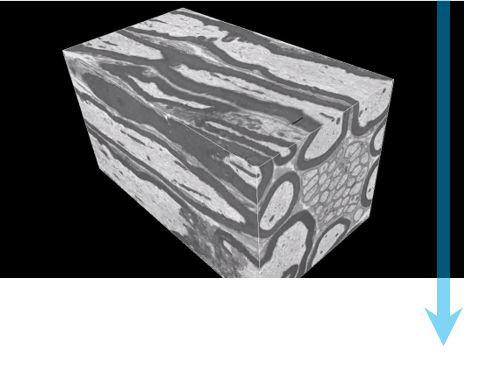

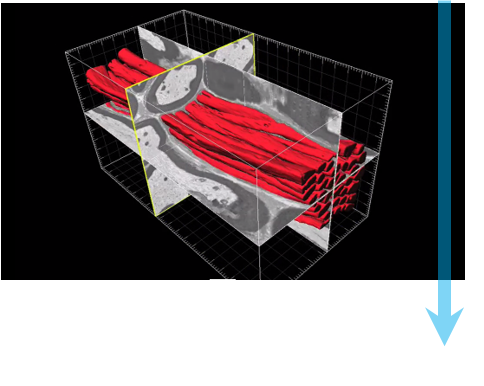

Step 5: Analyze The images are stacked to form a 3D dataset, which can be processed and viewed in DigitalMicrograph® or third-party software. At this point segmentation and quantification can be performed. |

DigitalMicrograph, also known as Gatan Microscopy Suite, drives your digital cameras and surrounding components to support key applications including tomography, in-situ, spectrum and diffraction imaging, plus more.

-

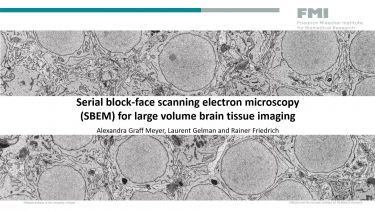

SBEM for large volume brain tissue imaging webinar

SBEM for large volume brain tissue imaging webinar

-

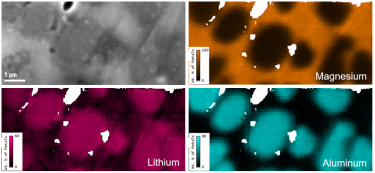

Quantitative mapping of lithium in the scanning electron microscope

Quantitative mapping of lithium in the scanning electron microscope

-

3D visualization of an individual intact chromosome

3D visualization of an individual intact chromosome

-

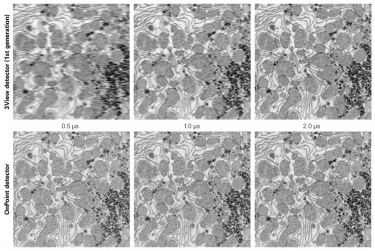

OnPoint detector minimizes charging and beam damage

OnPoint detector minimizes charging and beam damage

-

OnPoint increases 3View imaging speed four-fold

OnPoint increases 3View imaging speed four-fold

-

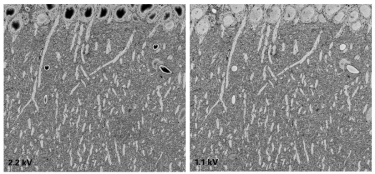

Preserves synaptic vesicle under low kV conditions

-

Large format image support is critical for throughput

Large format image support is critical for throughput

3D-CLEM reveals that a major portion of mitotic chromosomes is not chromatin

Booth, D. G.; Beckett, A. J.; Molina, O.; Samejima, I.; Masumoto, H.; Kouprina, N.; Larionov, V.; Prior, I. A.; Earnshaw, W. C.

Holcomb, P. S.; Hoffpauir, B. K.; Hoyson, M. C.; Jackson, D. R.; Deerinck, T. J.; Marrs, G. S.; Dehoff, M.; Wu, J.; Ellisman, M. H.; Spirou, G. A.

High-throughput 3D visualization of large volumes at high resolution by 3View

Dohnalkova, A.; Kennedy, D.; Mancuso, J.; Marshall, M.; Mainwaring, P.; Fredrickson, J.

Lead asparate, an en bloc contrast stain particularly useful for ultrastructural enzymology

Walton, J.

Morphology of phagophore precursors by correlative light-electron microscopy

Gudmundsson, S. R.; Kallio, K. A.; Vihinen, H.; Jokitalo, E.; Ktistakis, N.; Eskelinen, E. L.

Tanaka, T.; Ohno, N.; Osanai, Y.; Saitoh, S.; Thai, T. Q.; Nishimura, K.; Shinjo, T.; Takemura, S.; Tatsumi, K.; Wanaka, A.

Mitochondrial morphology and function: two for the price of one!

Faitg, J.; Davey, T.; Turnbull, D. M.; White, K.; Vincent, A. E.

Ultrastructural variability of the juxtacanalicular tissue along the inner wall of Schlemm’s canal

Koudouna, E.; Young, R. D.; Overby, D. R.; Ueno, M.; Kinoshita, S.; Knupp, C.; Quantock, A. J.

Hashimoto, T.; Thompson, G. E.; Zhou, X.; Withers, P. J.

The biosynthesis of infrared-emitting quantum dots in allium fistulosum

Green, M.; Haigh, S. J.; Lewis, E. A.; Sandiford, L.; Burkitt-Gray, M.; Fleck, R.; Vizcay-Barrena, G.; Jensen, L.; Mirzai, H.; Curry, R. J.; Dailey, L. -A.

Borrett, S.; Hughes, L.

Kreshuk, A.; Walecki, R.; Koethe, U.; Gierthmuehlen, M.; Plachta, D.; Genoud, C.; Haastert-Talini, K.; Hamprecht, F. A.

Froud, K. E.; Wong, A. C. Y.; Cederholm, J. M. E.; Klugmann, M.; Sandow, S. L.; Julien, J. -P.; Ryan, A. F.; Housley, G. D.

Challenges of microtome-based serial block-face scanning electron microscopy in neuroscience

Wanner, A. A.; Kirschmann, M. A.; Genoud, C.

High-resolution whole-brain staining for electron microscopic circuit reconstruction

Mikula, S.; Denk, W.

Comparison and combination of imaging techniques for three dimensional analysis of electrical trees

Schurch, R.; Rowland, S.M.; Bradley, R.S.; Withers, P.J.

The Lowe syndrome protein OCRL1 is required for endocytosis in the zebrafish pronephric tubule

Oltrabella, F.; Pietka, G.; Ramirez, I. B.-R.; Mironov, A.; Starborg, T.; Drummond, I. A.; Hinchliffe, K. A.; Lowe, M.

Starborg, T.; Kadler, K. E.

Three-dimensional architecture of podocytes revealed by block-face scanning electron microscopy

Ichimura, K.; Miyazaki, N.; Sadayama, S.; Murata, K.; Koike, M.; Nakamura, K. -I.; Ohta, K.; Sakai, T.

Hondow, N.; Brown, M. R.; Starborg, T.; Monteith, A. G.; Brydson, R.; Summers, H. D.; Rees, P.; Brown, A.

Analysis of primary cilia in the developing mouse brain

Paridaen, J. T. M. L.; Huttner, W. B.; Wilsch-Bräuninger, M.

How to bury the dead: elimination of apoptotic hair cells from the hearing organ of the mouse

Anttonen, T.; Belevich, I.; Kirjavainen, A.; Laos, M.; Brakebusch, C.; Jokitalo, E.; Pirvola, U.

Developing 3D SEM in a broad biological context

Kremer, A.; Lippens, S.; Bartunkova, S.; Asselbergh, B.; Blanpain, C.; Fendrych, M.; Goossens, A.; Holt, M.; Janessens, S.; Krols, M.; Larsimont, J. -C.; Mc Guire, C.; Nowack, M. K.; Saelens, X.; Schertel, A.; Schepens, B.; Slezak, M.; Timmerman, V.; Theunis, C.; Van Brempt, R.; Visser, Y.; Guerin, C. J.

Application of FEA to image-based models of electrical trees with uniform conductivity

Rowland, S. M.; Schurch, R.; Pattouras, M.; Li, Q.

RBM3 mediates structural plasticity and protective effects of cooling in neurodegeneration

Peretti, D.; Bastide, A.; Radford, H.; Verity, N.; Molloy, C.; Martin, M. G.; Moreno, J. A.; Steinert, J. R.; Smith, T.; Dinsdale, D.; Willis, A. E.; Mallucci, G. R.

Pinali, C.; Holt, C. M.; Bennett, H. J.; Davenport, J. B.; Walker, R.; Murfitt, L.; Allan, L. J.; Malik, N.; Kitmitto, A.

Kempen, P. J.; Kircher, M. F.; de la Zerda, A.; Zavaleta, C. L.; Jokerst, J. V.; Mellinghoff, I. K.; Gambhir, S. S.; Sinclair, R.

Quantitative analysis of mouse pancreatic islet architecture by serial block-face SEM

Pfeifer, C. R.; Shomorony, A.; Aronova, M. A.; Zhang, G.; Cai, T.; Xu, H.; Notkins, A. L.; Leapman, R. D.

Automated analysis of spine dynamics on live CA1 pyramidal cells

Blumer, C.; Vivien, C.; Genoud, C.; Perez-Alvarez, A.; Wiegert, J. S.; Vetter, T.; Oertner, T. G.

Advanced imaging and tissue engineering of the human limbal epithelial stem cell niche

Massie, I.; Dziasko, M.; Kureshi, A.; Levis, H. J.; Morgan, L.; Neale, M.; Sheth, R.; Tovell, V. E.; Vernon, A. J.; Funderburgh, J. L.; Daniels, J. T.

Automated analysis of spine dynamics on live CA1 pyramidal cells

Blumer, C.; Vivien, C.; Genoud, G.; Perez-Alvarez, A.; Wiegert, J. S.; Vetter, T.; Oertner, T. G.

Ju, W. K.; Kim, K. Y.; Noh, Y. H.; Hoshijima, M.; Lukas, T. J.; Ellisman, M. H.; Weinreb, R. N.; Perkins, G. A.

Finite element analysis of the pressure-induced deformation of Schlemm’s canal endothelial cells

Vargas-Pinto, R.; Lai, J.; Gong, H.; Ethier, C. R.; Johnson, M.

Serial block face-scanning electron microscopy: A method to study retinal degenerative phenotypes

Mustafi, D.; Kikano, S.; Palczewski, K.

Serial block face-scanning electron microscopy: a method to study retinal degenerative phenotypes

Mustafi, D.; Kikano, S.; Palczewski, K.

Staining and embedding of human chromosomes for 3-d serial block-face scanning electron microscopy

Yusuf, M.; Chen, B.; Hashimoto, T.; Estandarte, A. K.; Thompson, G.; Robinson, I.

Three-dimensional reconstruction of skeletal muscle extracellular matrix ultrastructure

Gillies, A. R.; Bushong, E. A.; Deerinck, T. J.; Ellisman, M. H.; Lieber, R. L.

The versatile electron microscope: An ultrastructural overview of autophagy

Biazik, J.; Vihinen, H.; Anwar, T.; Jokitalo, E.; Eskelinen, E.

Mission (im)possible – mapping the brain becomes a reality

Eberle, A. L.; Selchow, O.; Thaler, M.; Zeidler, D.; Kirmse, R.

Dynein light intermediate chains maintain spindle bipolarity by functioning in centriole cohesion

Jones, L. A.; Villemant, C.; Starborg, T.; Salter, A.; Goddard, G.; Ruane, P.; Woodman, P. G.; Papalopulu, N.; Woolner, S.; Allan, V. J.

Urwyler, O.; Izadifar, A.; Dascenco, D.; Petrovic, M.; He, H.; Ayaz, D.; Kremer, A.; Lippens, S.; Baatsen, P.; Guérin, C. J.; Schmucker, D.

En bloc staining with hydroquinone treatment for block face imaging

Togo, A.; Ohta, K.; Higashi, R.; Nakamura, K.

Pinali, C.; Kitmitto, A.

Pinali, C.; Kitmitto, A.

Three dimensional imaging of electrical trees in micro and nano-filled epoxy resin

Schurch, R.; Rowland, S.M.; Bradley, R.S.; Hashimoto, T.; Thompson, G.E.; Withers, P.J.

Three dimensional imaging of electrical trees in micro and nano-filled epoxy resin

Schurch, R.; Rowland, S. M.; Bradley, R. S.; Hashimoto, T.; Thompson, G. E.; Withers, P. J.

Finite-size effects in the 3D reconstruction and morphological analysis of porous polymers

Müllner, T.; Zankel, A.; Svec, F.; Tallarek, U.

Salloum, R. H.; Chen, G.; Velet, L.; Manzoor, N. F.; Elkin, R.; Kidd, G. J.; Coughlin, J.; Yurosko, C.; Bou-Anak, S.; Azadi, S.; Gohlsch, S.; Schneider, H.; Kaltenbach, J.A.

Salloum, R. H.; Chen, G.; Velet, L.; Manzoor, N. F.; Elkin, R.; Kidd, GJ.; Coughlin, J.; Yurosko, C.; Bou-Anak, S.; Azadi, S.; Gohlsch, S.; Schneider, H.; Kaltenbach, J.A.

A quantitative three-dimensional in situ study of a short fatigue crack in a magnesium alloy

Marrow, T. J.; Mostafavi, M.; Hashimoto, T.; Thompson, G. E.

A quantitative three-dimensional in situ study of a short fatigue crack in a magnesium alloy

Marrow, T. J.; Mostafavi, M.; Hashimoto, T.; Thompson, G. E.

Rhinomonas nottbecki n. sp. (cryptomonadales) and molecular phylogeny of the family pyrenomonadaceae

Majaneva, M.; Remonen, I.; Rintala, J. M.; Belevich, I.; Kremp, A.; Setälä, O.; Jokitalo, E.; Blomster, J.

Arabidopsis NAC45/86 direct sieve element morphogenesis culminating in enucleation

Furuta, K. M.; Yadav, S. R.; Lehesranta, S.; Belevich, I.; Miyashima, S.; Heo, J.; Vatén, A.; Lindgren, O.; De Rybel, B.; Van Isterdael, G.; Somervuo, P.; Lichtenberger, R.; Rocha, R.; Thitamadee, S.; Tähtiharju, S.; Auvinen, P.; Beeckman, T.; Jokitalo, E.; Helariutta, Y.

Tsai, W. T.; Hassan, A.; Sarkar, P.; Correa, J.; Metlagel, Z.; Jorgens, D. M.; Auer, M.

Busskamp, V.; Krol, J.; Nelidova, D.; Daum, J.; Szikra, T.; Tsuda, B.; Jüttner, J.; Farrow, K.; Scherf, B. G.; Alvarez, C. P.; Genoud, C.; Sothilingam, V.; Tanimoto, N.; Stadler, M.; Seeliger, M.; Stoffel, M.; Filipowicz, W.; Roska, B.

Miyazaki, N.; Esaki, M.; Ogura, T.; Murata, K.

Miyazaki, N.; Esaki, M.; Ogura, T.; Murata, K.

Heras-Bautista, C. O.; Katsen-Globa, A.; Schloerer, N. E.; Dieluweit, S.; El Aziz OM, A.; Peinkofer, G.; Attia, W. A.; Khalil, M.; Brockmeier, K.; Hescheler, J.; Pfannkuche, K.

Differential roles of microglia and monocytes in the inflamed central nervous system

Yamasaki, R.; Lu, H.; Butovsky, O.; Ohno, N.; Rietsch, A.M.; Cialic, R.; Wu, P. M.; Doykan, C. E.; Lin, J.; Cotleur, A. C.; Kidd, G.; Zorlu, M. M.; Sun, N.; Hu, W.; Liu, L.; Lee, J. C.; Taylor, S. E.; Uehlein, L.; Dixon, D.; Gu, J.; Floruta, C. M.; Zhu, M.; Charo, I. F.; Weiner, H. L.; Ransohoff, R. M.

Mitochondrial immobilization mediated by syntaphilin facilitates survival of demyelinated axons

Ohno, N.; Chiang, H.; Mahad, D. J.; Kidd, G. J.; Liu, L.; Ransohoff, R. M.; Sheng, Z. H.; Komuro, H. Trapp, B. D.

Cooperrider, J.; Furmaga, H.; Plow, E.; Park, H. J.; Chen, Z.; Kidd, G.; Baker, K. B.; Gale, J. T.; Machado, A. G.

Hughes, A. E.; Trinchi, A.; Chen, F. F.; Yang, Y. S.; Cole, I. S.; Sellaiyan, S.; Carr, J.; Lee, P. D.; Thompson, G. E.; Xiao, T. Q.

Serial sectioning methods for 3D investigations in materials science

Zankel, A.; Wagner, J.; Poelt, P.

Lipke, E.; Hörnschemeyer, T.; Pakzad, A.; Booth, C. R.; Michalik, P.

Lipke, E.; Hörnschemeyer, T.; Pakzad, A.; Booth, C. R.; Michalik, P.

Chen, B.; Hashimoto, T.; Vergeer, F.; Burgess, A.; Thompson, G.; Robinson, I.

Pinali, C.; Bennett, H. J.; Davenport, J. B.; Caldwell, J. L.; Trafford, A. W.; Kitmitto, A.

Pinali, C.; Bennett, H. J.;Davenport, J. B.; Caldwell, J. L.; Trafford, A. W.; Kitmitto, A.

Chen, B.; Hashimoto, T.; Vergeer, F.; Burgess, A.; Thompson, G.; Robinson, I.

Transcellular degradation of axonal mitochondria

Davis, C. O.; Kim, K.; Bushong, E. A.; Mills, E. A.; Boassa, D.; Shih, T.; Kinebuchi, M.; Phan, S.; Zhou, Y.; Bihlmeyer, N. A.; Nguyen, J. V.; Jin, Y.; Ellisman, M. H.; Marsh-Armstrong, N.

Revelation of intertwining organic and inorganic fractal structures in polymer coatings

Hughes, A. E.; Trinchi, A.; Chen, F. F.; Yang, Y. S.; Cole, I. S.; Sellaiyan, S.; Carr, J.; Lee, P. D.; Thompson, G. E.; Xiao, T. Q.

Dziasko, M. A.; Armer, H. E.; Levis, H. J.; Shortt, A. J.; Tuft, S.; Daniels, J. T.

Dziasko, M. A.; Armer, H. E.; Levis, H. J.; Shortt, A. J.; Tuft, S.; Daniels, J. T.

Wu, J.; Bakerink, K. J.; Evangelista, M. E.; Thomas, G. H.

Gillies, A.; Lieber, R.

ER sheet persistence is coupled to myosin 1c–regulated dynamic actin filament arrays

Joensuu, M.; Belevich, I.; Rämö, O.; Nevzorov, I.; Vihinen, H.; Puhka, M.; Witkos, T. M.; Lowe, M.; Vartiainen, M. K.; Jokitalo, E.

Serial block face scanning electron microscopy-the future of cell ultrastructure imaging

Hughes, L.; Hawes, C.; Monteith, S.; Vaughan, S.

An enteroendocrine cell-enteric glia connection revealed by 3D electron microscopy

Bohórquez, D. V.; Samsa, L. A.; Roholt, A.; Medicetty, S.; Chandra, R.;Liddle, R. A.

Pingel, J.; Lu, Y.; Starborg, T.; Fredberg, U.; Langberg, H.; Nedergaard, A.; Weis, M.; Eyre, D.; Kjaer, M.; Kadler, K. E.

Pingel, J.; Lu, Y.; Starborg, T.; Fredberg, U.; Langberg, H.; Nedergaard, A.; Weis, M.; Eyre, D.; Kjaer, M.; Kadler, K. E.

Resolution of the three dimensional structure of components of the glomerular filtration barrier

Arkill, K. P; Qvortrup, K.; Starborg, T.; Mantell, J. M.; Knupp, C.; Michel, C. C.; Harper, S. J.; Salmon, A. H. J.; Squire, J. M.; Bates, D. O.; Neal, C. R.

Three-dimensional aspects of matrix assembly by cells in the developing cornea

Young, R. D.; Knupp, C.; Pinali, C.; Png, K. M. Y.; Ralphs, J. R.; Bushby, A. J.; Starborg,T.; Kadler, K. E.; Quantock, A. J.

Wilke, S. A.; Raam, T.; Antonios, J. K.; Bushong, E. A.; Koo, E. H.; Ellisman, M. H.; Ghosh, A.

Exploring the third dimension: Volume electron microscopy comes of age

Peddie, C. J.; Collinson, L. M.

Resolution of three dimensional structure of components of the glomerular filtration barrier

Arkill, K. P.; Qvortrup, K.; Starborg, T.; Mantell, J. M.; Knupp, C.; Michel, C. C.; Harper, S. J.; Salmon, A. H. J.; Squire, J. M.; Bates, D. O.; Neal, C. R.

Hughes, L.; Towers, K.; Starborg, T.; Gull, K.; Vaughan, S.

The protein quality control system manages plant defence compound synthesis

Pollier, J.; Moses, T.; González-Guzmán, M.; De Geyter, N.; Lippens, S.; Bossche, R. V.; Marhavý, P.; Kremer, A.; Morreel, K.; Guérin, C. J.; Tava, A.; Oleszek, W.; Thevelein, J. M.; Campos, N.; Goormachtig, S.; Goossens, A.

Nonmuscle myosin II powered transport of newly formed collagen fibrils at the plasma membrane

Kalson, N. S.; Starborg, T.; Lu, Y.; Mironov, A.; Humphries, S. M.; Holmes, D. F.; Kadler, K. E.

Widespread mitochondrial depletion via mitiphagy does not compromise necroptosis

Tait, S. W.; Oberst, A.; Quarato, G.; Milasta, S.; Haller, M.; Wang, R.; Karvela, M.; Ichim, G.; Yatim, N.; Albert, M. L.; Kidd, G.; Wakefield, R.; Frase, S.; Krautwald, S.; Linkermann, A.; Green, D. R.

Pinali, C.; Bennett, H.; Davenport, J. B.; Trafford, A. W.; Kitmitto, A.

Kuwajima, M.; Spacek, J.; Harris, K. M.

Trueman, A.; Knight, S.; Colwell, J.; Hashimoto, T.; Carr, J.; Skeldon, P.; Thompson, G.

Connectomic reconstruction of the inner plexiform layer in the mouse retina

Helmstaedter, M.; Briggman, K. L.; Turaga, S. C.; Jain, V.; Seung, H. S.; Denk, W.

Hashimoto, T.; Thompson, G. E.; Curioni, M.; Zhou, X. R.; Skeldon, P.

Dwyer, L.; Robson, J.; da Fonseca, J. Q.; Kamp, N.; Hashimoto, T.; Thompson, G. E.

Construction of a polarized neuron

Holcomb, P. S.; Deerinck, T. J.; Ellisman, M. H.; Spirou, G. A.

Three dimensional electron microscopy of cellular organelles by serial block face SEM and ET

Vihinen, H.; Belevich, I.; Jokitalo, E.

Wong, J.; Baddeley, D.; Bushong, E. A.; Yu, Z.; Ellisman, M. H.; Hoshijima, M.; Soeller, C.

Functional development of the olfactory system in zebrafish

Miyasaka, N.; Wanner, A. A.; Li, J.; Mack-Bucher, J.; Genoud, C.; Yoshihara, Y.; Friedrich, R. W.

BMP signaling specifies the development of a large and fast CNS synapse

Xiao, L.; Michalski, N.; Kronander, E.; Gjoni, E.; Genoud, C.; Knott, G.; Schneggenburger, R.

DP2: Distributed 3D image segmentation using micro-labor workforce

Giuly, R. J.; Kim, K. Y.; Ellisman, M. H.

Shigetomi, E.; Bushong, E. A.; Haustein, M. D.; Tong, X.; Jackson-Weaver, O.; Kracun, S.; Xu, J.; Sofroniew, M. V.; Ellisman, M. H.; Khakh, B. S.

Analyzing the structure and function of neuronal circuits in zebrafish

Friedrich, R. W.; Genoud, C.; Wanner, A. A.

WDR81 is necessary for purkinje and photoreceptor cell survival

Traka, M.; Millen, K. J.; Collins, D.; Elbaz, B.; Kidd, G. J.; Gomez, C. M.; Popko, B.

Large-scale automatic reconstruction of neuronal processes from electron microscopy images

Kaynig, V.; Vazquez-Reina, A.; Knowles-Barley, S.; Roberts, M.; Jones, T. R.; Kasthuri, N.; Miller, E.; Lichtman, J.; Pfister, H.

Boassa, D.; Berlanga, M. L.; Yang, M. A.; Terada, M.; Hu, J.; Bushong, E. A.; Hwang, M.; Masliah, E.; George, J. M.; Ellisman, M. H.

Revealing the three dimensional internal structure of aluminium alloys

Thompson, G. E.; Hashimoto, T.; Zhong, X. L.; Curioni, M.; Zhou, X.; Skeldon, P.; Withers, P. J.; Carr, J. A.; Monteith, A. G.

Jurrus, E.; Watanabe, S.; Giuly, R. J.; Paiva, A. R.; Ellisman, M. H.; Jorgensen, E. M.; Tasdizen, T.

Wilke, S. A.; Antonios, J. K.; Bushong, E. A.; Badkoobehi, A.; Malek, E.; Hwang, M.; Terada, M.; Ellisman, M. H.; Ghosh, A.

Autosomal recessive retinitis pigmentosa E150K opsin mice exhibit photoreceptor disorganization

Zhang, N.; Kolesnikov, A. V.; Jastrzebska, B.; Mustafi, D.; Sawada, O.; Maeda, T.; Genoud, C.; Engel, A.; Kefalov, V. J.; Palczewski, K.

Starborg, T.; Kalson, N. S.; Lu, Y.; Mironov, A.; Cootes, T. F.; Holmes, D. F.; Kadler, K. E.

Paridaen, J. T. M. L.; Wilsch-Bräuninger, M.; Huttneremail, W. B.

Three-dimensional structure analysis and percolation properties of a barrier marine coating

Chen, B.; Guizar-Sicairos,M.; Xiong,G.; Shemilt, L.; Diaz, A.; Nutter, J.; Burdet,N.; Huo,S.; Mancuso, J.; Monteith,A.; Vergeer,F.; Burgess,A.; Robinson, I.

Anttonen, T.; Kirjavainen, A.; Belevich, I.; Laos, M.; Richardson, W. D.; Jokitalo, E.; Brakebusch, C.; Pirvola, U.

Müllner, T.; Zankel, A.; Mayrhofer, C.; Reingruber, H.; Höltzel, A.; Lv, Y.; Svec, F.; Tallarek, U.

Investigation of dealloying by ultra-high-resolution nanotomography

Hashimoto, T.; Curioni, M.; Zhou, X.; Mancuso, J.; Skeldon, P.; Thompson, G. E.

Schwartz, C. L.; Heumann, J. M.; Dawson, S. C.; Hoenger,A.

Prdm3 and Prdm16 are H3K9me1 methyltransferases required for mammalian heterochromatin integrity

Pinheiro, I.; Margueron, R.; Shukeir, N.; Eisold, M.; Fritzsch, C.; Richter, F. M.; Mittler, G.; Genoud, C.; Goyama, S.; Kurokawa, M.; Son, J.; Reinberg, D.; Lachner, M.; Jenuwein, T.

Puhka, M.; Joensuu, M.; Vihinen, H.; Belevich, I.; Jokitalo, E.

Zhuravleva, E.; Gut, H.; Hynx, D.; Marcellin, D.; Bleck, C. K.; Genoud, C.; Cron, P.; Keusch, J. J.; Dummler, B.; Esposti, M. D.; Hemmings, B. A.

Azeloglu, E.; Stothers, M.; Deerinck, T. J.; Falkenberg, C.; Chen, Y.; He, J. C.; Hone, J. C.; Leslie, L. M.; Ellisman, M. H.; Iyengar, R.

Extrusion of misfolded and aggregated proteins--a protective strategy of aging neurons?

Doehner, J.; Genoud, C.; Imhof, C.; Krstic, D.; Knuesel, I.

3D segmentation of SBFSEM images of neuropil by a graphic model over supervoxel boundaries

Andres, B.; Koethe, U.; Kroeger, T.; Helmstaedter, M.; Briggman, K. L.; Denk, W.; Hamprecht, F. A.

Differential modulation of retinal degeneration by Ccl2 and Cx3cr1 chemokine signalling

Luhmann, U. F.; Lange, C. A.; Robbie, S.; Munro, P. M.; Cowing, J. A.; Armer, H. E.; Luong, V.; Carvalho, L. S.; MacLaren, R. E.; Fitzke, F. W.; Bainbridge, J.W.; Ali, R. R.

Beam deceleration for block-face scanning electron microscopy of embedded biological tissue

Ohta, K.; Sadayama, S.; Togo, A.; Higashi, R.; Tanoue, R.; Nakamura, K.

Multivesicular exocytosis in rat pancreatic beta cells

Hoppa, M. B.; Jones, E.; Karanauskaite, J.; Ramracheya, R.; Braun, M.; Collins, S. C.; Zhang, Q.; Clark, A.; Eliasson, L.; Genoud, C.; Macdonald, P. E.; Monteith, A. G.; Barg, S.; Galvanovskis, J.; Rorsman, P.

Structural neurobiology: Missing link to a mechanistic understanding of neural computation

Denk, W.; Briggman, K. L.; Helmstaedter, M.

Giuly, R. J.; Martone, M. E.; Ellisman, M. H.

Volume electron microscopy for neuronal circuit reconstruction

Briggman, K. L.; Bock, D. D.

Yan, J.; Walker, C. G.; O'sullivan, M. J.; Bushong, E. A.; Ellisman, M. H.; Hoshijima, M.; Rajagopal, V.

High contrast en bloc staining of neuronal tissue for field emission scanning electron microscopy

Tapia, J. C.; Kasthuri, N.; Hayworth, K. J.; Schalek, R.; Lichtman, J. W.; Smith, S. J.; Buchanan, J.

Ou, H. D.; Kwiatkowski, W.; Deerinck, T. J.; Noske, A.; Blain, K. Y.; Land, H. S.; Soria, C.; Powers, C. J.; May, A. P.; Shu, X.; Tsien, R. Y.; Fitzpatrick, J. A. J.; Long, J. A.; Ellisman, M. H.; Choe, S.; O'Sheaemail, C. C.

Modern electron microscopy methods for C. elegans

Hall, D. H.; Hartwieg, E.; Nguyen, K. C.

Mustafi, D.; Kevany, B. M.; Genoud, C.; Okano, K.; Cideciyan, A. V.; Sumaroka, A.; Roman, A. J.; Jacobson, S. G.; Engel, A.; Adams, M. D.; Palczewski, K.

Motskin, M.; Müller, K. H.; Genoud, C.; Monteith, A. G.; Skepper, J. N.

Fast extraction of neuron morphologies from large-scale SBFSEM image stacks

Lang, S.; Drouvelis, P.; Tafaj, E.; Bastian, P.; Sakmann, B.

Kalson, N. S.; Holmes, D. F.; Herchenhan, A.; Lu, Y.; Starborg, T.; Kadler, K. E.

Wong, J. I. S.; Baddeley, D.; Bushong, E. A.; Ellisman, M.; Hoshijima, M.; Soeller, C.

Mun, J. Y.; Jeong, S. Y.; Kim, J. H.; Han, S. S.; Kim, I. H.

Basement membrane changes in capillaries of the ageing human retina

Powner, M. B.; Scott, A.; Zhu, M.; Munro, P. M.; Foss, A. J.; Hageman, G. S.; Gillies, M. C.; Fruttiger, M.

Cadherin-9 regulates synapse-specific differentiation in the developing hippocampus

Williams, M. E.; Wilke, S. A.; Daggett, A.; Davis, E.; Otto, S.; Ravi, D.; Ripley, B.; Bushong, E. A.; Ellisman, M. H.; Klein, G.; Ghosh, A.

High-accuracy neurite reconstruction for high-throughput neuroanatomy

Helmstaedter, M.; Briggman, K. L.; Denk, W.

Role of elastin anisotropy in structural strain energy functions of arterial tissue

Rezakhaniha, R.; Fonck, E.; Genoud, C.; Stergiopulos, N.

Modeling of flow in a polymeric chromatographic monolith

Koku, H.; Maier, R. S.; Czymmek, K. J.; Schure, M. R.; Lenhoff, A. M.

Quantitative Characterisation of microfiltration membranes by 3D reconstruction

Reingruber, H.; Zankel, A.; Mayrhofer, C.; Poelt, P.

Shu, X.; Lev-Ram, V.; Deerinck, T. J.; Qi, T.; Ramko, E. B.; Davidson, M. W.; Jin, Y. Ellisman, M. H.; Tsien, R. Y.

Wiring specificity in the direction-selectivity circuit of the retina

Briggman, K. L.; Helmstaedter, M.; Denk, W.

Nguyen, J. V.; Soto, I.; Kim, K.; Bushong, E. A.; Oglesby, E.; Valiente-Soriano, F. J.; Yang, Z.; Davis, C. O.; Bedont, J. L.; Son, J. L.; Wei, J. O.; Buchman, V. L.; Zack, D. J.; Vidal-Sanz, M.; Ellisman, M. H.; Marsh-Armstrong, N.

Environmental scanning electron microscopy (ESEM)--a versatile tool in studying plants.

Stabentheiner, E.; Zankel A.; Pölt P.

Jurrus, E.; Paiva, A. R.; Watanabe, S.; Anderson, J. R.; Jones, B. W.; Whitaker, R. T.; Jorgensen, E. M.; Marc, R. E.; Tasdizen, T.

Reconstruction of a neuron from SBFSEM: tools, reliability, accuracy and efficiency

Drouvelis, P.; Kurz, T.; Bastian, P.; Sakmann, B.; Lang, S.

Deerinck, T. J.; Bushong, E. A.; Lev-Ram, V.; Shu, X.; Tsien, R. Y.; Ellisman, M. H.

Structure-function studies of blood and air capillaries in chicken lung using 3D electron microscopy

West, J. B.; Fu, Z.; Deerinck, T. J.; Mackey, M. R.; Obayashi, J. T.; Ellisman, M.H.

Imaging transient blood vessel fusion events in zebrafish by correlative volume electron microscopy

Armer, H. E. J.; Mariggi, G.; Png, K. M. Y.; Genoud, C.; Monteith, A. G.; Bushby, A. J.; Gerhardt, H.; Collinson, L. M.

Saetzler, K.; McCanny, P.; Rodriguez, E.P.; Horstmann, H.; Bruno, R.M.; Denk, W.

Axon tracking in serial block-face scanning electron microscopy

Jurrus, E.; Hardy, M.; Tasdizen, T.; Fletcher, P. T.; Koshevoy, P.; Chien, C. B.; Denk, W.; Whitaker, R.

Mishchenko, Y.

Three-dimensional reconstruction methods for Caenorhabditis elegans ultrastructure

Müller-Reichert, T.; Mancuso, J.; Lich, B.; McDonald, K.

Ultramicrotomy in the ESEM, a versatile method for materials and life sciences

Zankel, A.; Kraus, B.; Poelt, P.; Schaffer, M.; Ingolic, E.

Genoud, C.; Mancuso, J.; Monteith, S.; Kraus, B.

Contour-propagation algorithms for semi-automated reconstruction of neural processes

Macke, J. H.; Maack, N.; Gupta, R.; Denk, W.; Schölkopf, B.; Borst, A.

Segmentation of SBFSEM volume data of neural tissue by hierarchical classification

Andres, B.; Köthe, U.; Helmstaedter, M.; Denk, W.; Hamprecht, F. A.

Alpha-herpesvirus infection induces the formation of nuclear actin filaments

Feierbach, B.; Piccinotti, S.; Bisher, M.; Denk, W.; Enquist, L. W.

Serial block-face scanning electron microscopy to reconstruct three-dimensional tissue nanostructure

Denk, W.; Horstmann, H.

Applications

|

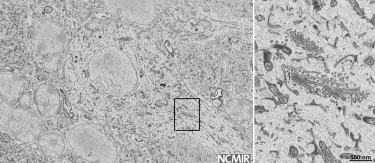

Optimizing three-dimensional electron microscopy results at low kV |

Protocols

3View recipes

3View quick start guide

3View diamond knife cleaning procedure

NCMIR methods for 3D EM: A new protocol for preparation of biological specimens for serial block-face scanning electron microscopy

OTO fixation for SEM and block-face imaging

Using transmission electron microscopy and 3View to determine collagen fibril size and three-dimensional organization (Nature video)