Bulk heating holders

- Precise temperature control of specimen holder tip is maintained using a bulk furnace and a water cooled specimen rod

- Heat loss from furnace to specimen tip is minimized using specialized ceramic furnace supports

| Gatan model number | Maximum temperature1 (°C) |

Furnace | Specimen positioning | Specimen securing | Maximum electrical feedthroughs |

|---|---|---|---|---|---|

| 628 | 1300 |

Tantalum |

α tilt | Hexring® mechanism |

6 |

| 628 | 900 | Inconel | α tilt | Hexring mechanism |

6 |

| 652 | 1000 | Tantalum | α, β tilt | Hexring mechanism |

2 – 62 |

| 652 | 850 | Inconel | α, β tilt | Hexring mechanism |

2 – 62 |

2Optional 2 – 6 for JEOL UHR, 2 maximum for other EMMs

Metastable hexagonal close-packed palladium hydride in liquid cell TEM

Hong, J.; Bae, J. -H.; Jo, H.; Park, H. -Y.; Lee, S.; Hong, S. J.; Chun, H.; Cho, M. K.; Kim, J.; Kim, J.; Son, Y.; Jin, H.; Suh, J. -Y.; Kim, S. -C.; Roh, H. -K.; Lee, K. H.; Kim, H. -S.; Chung, K. Y.; Yoon, C. W.; Lee, K.; Kim, S. H.; Ahn, J. -P.; Baik, H.; Kim, G. H.; Han, B.; Jin, S.; Hyeon, T.; Park, J.; Son, C. Y.; Yang, Y.; Lee, Y. -S.; Yoo, S. J.; Chun, D. W.

Lin, Z.; Wu, C.; He, H.; Jiang, S.; Ren, F.; Cao, L.; Huang, Z.; Zhang, J.

Direct visualization of the earliest stages of crystallization

Singh, M. K.; Ghosh, C.; Miller, B.; Carter, C. B.

He, L.; Ji, Y.; Ren, S.; Zhao, L.; Luo, H.; Liu, C.; Hao, Y.; Zhang, L.; Zhang, L.; Ren, X.

Lotnyk, A.; Dankwort, T.; Hilmi, I.; Kienle, L.; Rauschenbach, B.

Attapulgite-CeO2/MoS2 ternary nanocomposite for photocatalytic oxidative desulfurization

Li, X.; Zhang, Z.; Yao, C.; Lu, X.; Zhao, X.; Ni, C.

Surface crystallization of liquid Au–Si and its impact on catalysis

Panciera, F.; Tersoff, J.; Gamalski, A. D.; Reuter, M. C.; Zakharov, D.; Stach, E. A.; Hofmann, S.; Ross, F. M

In situ observation of resistive switching in an asymmetric graphene oxide bilayer structure

Kim, S.; Jung, H. J.; Kim, J. C.; Lee, K. -S.; Park, S. S.; Dravid, V. P.; He, K.; Jeong, H. Y.

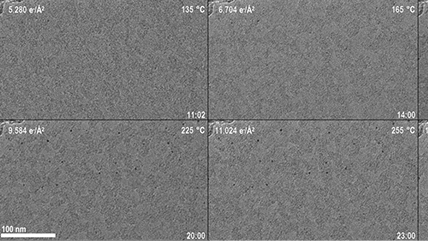

Mapping thermal expansion coefficients in freestanding 2D materials at the nanometer scale

Hu, X.; Yasaei, P.; Jokisaari, J.; Öğüt, S.; Salehi-Khojin, A.; Klie, R. F.

Hou, Z.; Zhang, Q.; Xu, G.; Gong, C.; Ding, B.; Wang, Y.; Li, H.; Liu, E.; Xu, F.; Zhang, H.; Yao, Y.; Wu, G.; Zhang, X. - X.; Wang, W.

First transparent oxide ion conducting ceramics synthesized by full crystallization from glass

Boyer, M.; Yang, X.; Carrión, A. J. F.; Wang, Q.; Véron, E.; Genevois, C.; Hennet, L.; Matzen, G.; Suard, E.; Thiaudière, D.; Castro, C.; Pelloquin, D.; Kong, L. B.; Kuang, X.; Allix, M.

Gao, J.; Liu, Y.; Wang, Y.; Wang, D.

Han, C. W.; Choksi, T.; Milligan, C.; Majumdar, P.; Manto, M.; Cui, Y.; Sang, X.; Unocic, R. R.; Zemlyanov, D.; Wang, C.; Ribeiro, F. H.; Greeley, J.; Ortalan, V.

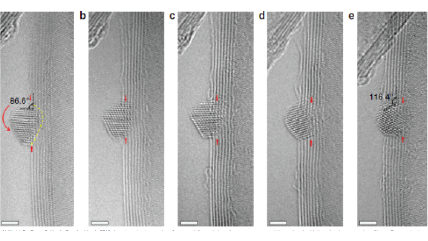

In situ observation of twin boundary sliding in single crystalline Cu nanowires

Yue, Y.; Zhang, Q.; Zhang, X.; Yang, Z.; Yin, P.; Guo, L.

Hwang, S.; Lee, Y.; Jo, E.; Chung, K. Y.; Choi, W.; Kim, S. M.; Chang, W.

Rao, J. C.; Diao, H. Y.; Ocelík, V.; Vainchtein, D.; Zhang, C.; Kuo, C.; Tang, Z.; Guo, W.; Poplawsky, J. D.; Zhou, Y.; Liaw, P. K.; De Hosson, J. Th. M.

Nanoscale engineering in VO2 nanowires via direct electron writing process

Zhang, Z.; Guo, H.; Ding, W.; Zhang, B.; Lu, Y.; Ke, X.; Liu, W.; Chen, F.; Sui, M.

Simple synthesis of highly uniform bilayer-carbon nanocages

Ziolkowska, D. A.; Jangam, J. S. Dilip; Rudakov, G.; Paronyan, T.; Akhtar, M.; Sumanasekera, G.; Jasinski, J. B.

Size-controllable fabrication of Cu nanoparticles on carbon nanotubes by simple heating

Liu, C.; Wu, S.; Zheng, H.; Cao, F.; Sheng, H.; Zhao, D.; Wang, J.

Synthesis engineering of iron oxide raspberry-shaped nanostructures

Gerber, O.; Pichon, B. P.; Ihiawakrim, D.; Florea, I.; Moldovan, S.; Ersen, O.; Begin, D.; Grenèche, J. -M.; Lemonnier, S.; Barraud, E.; Begin-Colin, S.

In situ XRD and TEM studies of sol-gel-based synthesis of LiFePO4

Ziolkowska, D. A.; Jasinski, J. B.; Hamankiewicz, B.; Korona, K. P.; Wu, S. -H.; Czerwinsk, A.

Stability of platinum nanoparticles supported on surface-treated carbon black

Kameya, Y.; Hayashi, T.; Motosuke, M.

The chemistry and structural thermal stability of hole-doped single crystalline SnSe

Zhang, B.; Peng, K.; Li, A.; Zhou, X.; Chen, Y.; Deng, Q.; Han, X.

Stability of platinum nanoparticles supported on surface-treated carbon black

Motosuke, M.

Marín, L.; Warot-Fonrose, B.; Estève, A.; Chabal, Y. J.; Rodriguez, L. A.; Rossi, C.

Ion irradiation induced disappearance of dislocations in a nickel-based alloy

Chen, H. C.; Li, D. H.; Lui, R. D.; Huang, H. F.; Li, J. J.; Lei, G. H.; Huang, Q.; Bao, L. M.; Yan, L.; Zhou, X. T.; Zhu, Z. Y.

Eggeler, Y. M.; Müller, J.; Titus, M. S.; Suzuki, A.; Pollock, T. M.; Spiecker, E.

Eggeler, Y. M.; J. Müller, J.; Titus, M. S.; Spiecker, E.

The formation mechanism of Janus nanostructures in one-pot reactions: the case of Ag–Ag8GeS6

van Embden, J.; Bourgeois, L.; Gaspera, E. D.; Waddington, L.; Yin, Y.; Medhekar, N. V.; Jasieniak, J. J.; Chesman, A. S. R.

Thermite synthesis and characterization of Co-ZrO2 ferromagnetic nanocomposite thin films

Myagkov, V. G.; Zhigalov, V. S.; Bykova, L. E.; Bondarenko, G. N.

Thermal stability comparison of nanocrystalline Fe-based binary alloy pairs

Clark, B. G.; Hattar, K. M.; Marshall, M. T.; Chookajorn, T.; Boyce, B. L.; Schuh, C. A.

Fu, X.; Warot-Fonrose, B.; Arras, R.; Seine, G.; Demaille, D.; Eddrief, M.; Etgens, V.; Serin, V.

Chen, Y. -J.; Zhang, B.; Ding, Q. -Q.; Deng, Q. -S.; Chen, Y.; Song, Z. -T.; Li, J. -X.; Zhang, Z.; Han, X. -D.

Manipulation of free volumes in a metallic glass through Xe-ion irradiation

Bian, X. L.; Wang, G.; Chine, H. C.; Yan, L.; Wang, J. G.; Wang, Q.; Hu, P. F.; Ren, J. L.; Chan, K. C.; Zheng, N.; Teresiak, A.; Gao, Y. L.; Zhai, Q. J.; Eckert, J.; Beadsworth, J.; Dahmen, K. A.; Liaw, P. K.

Direct observation of hydrogenation and dehydrogenation of a zirconium alloy

Shen, H. H.; Zu, X. T.; Chen, B.; Huang, C. Q.; Sun, K.

Wang, L. W.; Cheng, C. F.; Liao, J. W.; Wang, C. Y.; Wang, D. S.; Huang, K. F.; Lin, T. Y.; Ho, R. M.; Chen, L. J.; Lai, C. H.

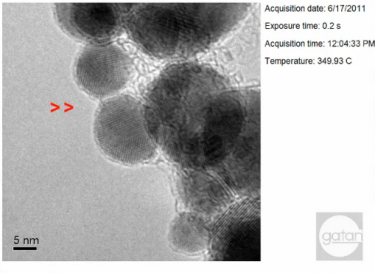

Van den Ber, R.; Elkjaer, C. F.; Gommes, C. J.; Chorkendorff, I.; Sehested, J.; de Jongh, P. E.; de Jongh, K. P.; Helveg, S.

Geometric and chemical composition effects on healing kinetics of voids in Mg-bearing Al alloys

Song, M.; Du, K.; Wang, C.; Wen, S.; Huang, H. Nie, Z.; Ye, H.

van den Berg, R.; Elkjaer, C. F.; Gommes, C. J.; Chorkendorff, I.; Sehested, J.; de Jongh, P. E.; de Jong, K. P.; Helveg, S.

Electron energy loss spectroscopy analysis of the interaction of Cr and V with MWCNTs.

Ilari, G. M.; Chawla, V.; Matam, S.; Zhang, Y.; Michler, J.; Erni, R.

Chen, Y.; Zhang, B.; Ding, D. -D.; Han, X. -D.

In situ observation on dislocation-controlled sublimation of Mg nanoparticles

Yu, Q.; Mao, M. -M.; Li, Q. -J.; Fu, X. -Q.; Tian, H.; Li, J. -X.; Mao, S. X.; Zhang, Z.

Chen, C.; Hu, Z.; Li, Y.; Liu, L.; Mori, H.; Wang, Z.

Luo, L.; Zou, L.; Schreiber, D. K.; Olszta, M. J.; Baer, D. R.; Bruemmer, S. M.; Zhou, G.; Wang, C. -M.

Jeangros, Q.; Aebersold, A. B.; Hébert, C.; Hessler-Wyser, A.

Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi

Zhang, Z.; Mao, M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.; George, E.; Yu, Q.; Ritchie, R.

Wang, L.; Gao, T.; Yu, Y.

In situ TEM observation of helium bubble evolution in V/Ag multilayer during annealing

Zhang, H.; Ren, F.; Wang, Y.; Hong, M.; Xiao, X.; Qin, W.; Jiang, C.

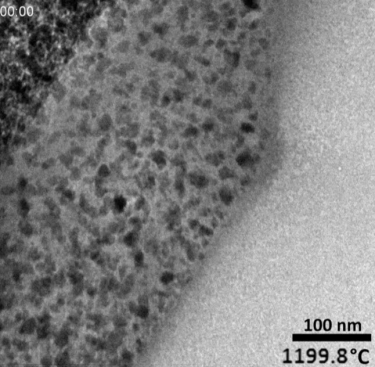

Thermal stability of fission gas bubble superlattice in irradiated U–10Mo fuel

Gan, J.; Keiser, D. D.; Miller, B. D.; Robinson, A. B.; Wachs, D. M.; Meyer, M. K.

In-situ synthesis of Ag nanoparticles by electron beam irradiation

Jiangfeng, G.; Jiangfeng, G.; Hongwei, L.; Yuwen, J.; Ringer, S.

Characterization of zirconium hydrides in Zircaloy-4 cladding with respect to cooling rate

Kim, S. -D.; Rhyim, Y.; Kim, J, -S.; Yoon, J.

Acosta, M.; Schmitt, L. A.; Molina-Luna, L.; Scherrer, M. C.; Brilz, M.; Webber, K. G.; Deluca, M.; Kleebe, H.; Rödel, J.; Donner, W.

Acosta, M.; Schmitt, L. A.; Molina-Luna, L.; Scherrer, M. C.; Brilz, M.; Webber, K. G.; Deluca, M.; Kleebe, H. -J.; Rödel, J.; Donner, W.

Helium bubble evolution in a Zr–Sn–Nb–Fe–Cr alloy during post-annealing: An in-situ investigation

Shen, H. H.; Peng, S. M.; Chen, B.; Naab, F. N.; Sun, G. A.; Zhou, W.; Xiang, X.; Sun, K.; Zu, X. T.

Direct observation of the crystal structure changes in the MgxZn1 − xO alloy system

Yoo, S. J.; Lee, J. -H.; Kim, C. -Y.; Kim, J. -G.

Muntifering, B.; Kovarik, L.; Browning, N. D.; Pond, R. C.; Knowlton, W. B.; Müllner, P.

Transition of dislocation nucleation induced by local stress concentration in nanotwinned copper

Lu, N.; Du, K.; Lu, L.; Ye, H. Q.

Boyes, E. D.; Gai, P. L.

Szkudlarek, A.; Vaz, A. R.; Zhang, Y.; Rudkowski, A.; Kapusta, C.; Erni, R.; Moshkalev, S.; Utke, I.

Effect of temperature on the nano/microstructure and mechanical behavior of nanotwinned Ag films

Zhang, H.; Geng, J.; Ott, R. T.; Besser, M. F.; Kramer, M. J.

Winkler, N.; Peterlechner, M.; Wilde, G.

Hwang, S.; Kim, S. M.; Bak, S-, M.; Kim. S. Y.; Cho, B-, W.; Chung, K. Y.; Lee, J. Y.; Stach, E. A.; Chang, W.

Satoh, Y.; Abe, H.; Matsukawa, Y.; Matsunaga, T.; Kano, S.; Arai, S.; Yamamoto, Y.; Tanaka, N.

Agarwal, R.; Zakharov, D. N.; Krook, N. M.; Liu, W.; Berger, J. S.; Stach, E. A.; Agarwal, R.

Kameche, F.; Ngo, A-, T.; Salzemann, C.; Cordeiro, M.; Sutter, E.; Petit, C.

Laser-induced reductive sintering of nickel oxide nanoparticles under ambient conditions

Paeng, D.; Lee, D.; Yeo, J.; Yoo, J. -H.; Allen, F. I.; Kim, E.; So, H.; Park, H. K.; Minor, A. M.; Grigoropoulos, C. P.

Evidence of the hydrogen release mechanism in bulk MgH2

Nogita, K.; Tran, X. Q.; Yamamoto, T.; Tanaka, E.; McDonald, S. D.; Gourlay, C. M.; Yasuda, K.; Matsumura, S.

Multiformity and fluctuation of Cu ordering in Cu2Se thermoelectric materials

Lu, P.; Liu, H.; Yuan, X.; Xu, F.; Shi, X.; Zhao, K.; Qiu, W.; Zhang, W.; Chen, L.

Liu, J. F.; Yang, Z. Q.; Ye, H. Q.

Liu, J.; Yang, Z.; Ye, H.

Formation and structure of V–Zr amorphous alloy thin films

King, D.; Middleburgh, S. C.; Liu, A. C. Y.; Cortie, M. B.

Mølgaard, M. P.; Hansen, T. W.; Birkedal, W. J.; Degn, J. A.

Schmitt, L. A.; Kungl, H.; Hinterstein, M.; Riekehr, L.; Kleebe, H. -J.; Hoffmann, M. J.; Eichel, R. -A.; Fuess, H.

Abnormalities associated with grain growth in solid solution Cu(Ni) thin films

Brons, J. G.; Thompson, G. B.

In-situ TEM study of stability of TaRhx diffusion barriers using a novel sample preparation method

Dalili, N.; Li, P.; Kupsta, M.; Liu, Q.; Ivey, D. G.

Gai, P. L.; Lari, L.; Ward, M. R.; Boyes, E. D.

Noncrystalline-to-Crystalline Transformations in Pt Nanoparticles

Li, L.; Wang, L.; Johnson, D. D.; Zhang, Z.; Sanchez, S. I.; Kang, J. H.; Nuzzo, R. G.; Wang, Q.; Frenkel, A. I.; Li, J.; Ciston, J.; Stach, E. A.; Yang, J. C.

Gandman, M.; Kauffmann, Y.; Koch, C. T.; Kaplan, W. D.

Bak, S.; Nam, K.; Chang, W.; Yu, x.; Hu, E.; Hwang, S.; Stach, E. A.; Kim, K.; Chung, K. Y.; Yang, X.

Gold catalyzed nickel disilicide formation: A new solid–liquid-solid phase growth mechanism

Tang, W.; Picraux, S. T.; Huang, J. H.; Liu, X.; Tu, K. N.; Dayeh, S. A.

Reduction of nickel oxide particles by hydrogen studied in an environmental TEM

Jeangros, Q.; Hansen, T. W.; Wagner, J. B.; Damsgaard, C. D.; Dunin-Borkowski, R. E.; Hébert, C.; Van herle, J.; Hessler-Wyser, A.

Yu, B.; Liu, W.; Chen, S.; Wang, H.; Wang, H.; Chen, G.; Ren, Z.

Copper ion liquid-like thermoelectrics

Liu, H.; Shi, X.; Xu, F.; Zhang, L.; Zhang, W.; Chen, L.; Li, Q.; Uher, C.; Day, T.; Snyder, G. J.

High-resolution in situ and ex situ TEM studies on graphene formation and growth on Pt nanoparticles

Penga, Z.; Somodia, F.; Helveg, S.; Kisielowski, C.; Specht, P.; Bell, A. T.

Anisotropic nanocrystal dissolution observation by in situ transmission electron microscopy

Cordeiro, M. A. L.; Crozier, P. A.; Leite, E. R.

Majidi, H.; Winkler, C. R.; Taheri, M. L.; Baxter, J. B.

Lattice modulation and superelasticity in oxygen-added β-Ti alloys

Tahara, M.; Kim, H. Y.; Inamura, T.; Hosoda, H.; Miyazaki, S.

Ciston, J.; Si, R.; Rodriguez, J. A.; Hanson, J. C.; Martinez-Arias, A.; Fernandez-Garcia, M.; Zhu, Y.

Janbroers, S.: Crozierc, P. A.; Zandbergen, H. W.; Kooyman, P. J.

Real-time observation of impurity diffusion in silicon nanowires

Holmberg, V. C.; Collier, K. A.; Korgel, B. A.

Ceria-catalyzed soot oxidation studied by environmental transmission electron microscopy

Simonsen, S. B.; Dahl, S.; Johnson, E.; Helveg, S.

Models 628, 652

Datasheets

Single Tilt Heating Holder, model 628

Double Tilt Heating Holder, model 652

Application notes and Experiment briefs

Related products

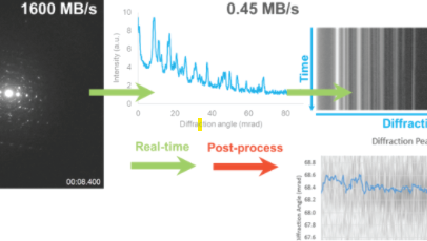

In-situ Explorer Software

Solarus® II System

Turbo Pumping Station

Gatan Microscopy Suite® Software