Micro x-ray fluorescence (micro-XRF) is a non-destructive analytical technique that provides spatially resolved elemental analysis of a wide range of materials. By focusing an x-ray beam to a small spot size, micro-XRF enables high-resolution elemental mapping and quantitative analysis, making it ideal for applications in materials science, forensics, geology, electronics, and cultural heritage.

What is micro-XRF? Advantages Workflow for micro-XRF

What is micro-XRF?

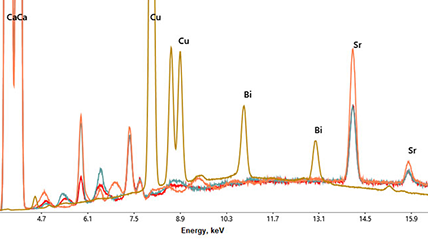

Micro-XRF works by directing a focused x-ray beam onto a sample, which causes the emission of characteristic secondary (fluorescent) x-rays from the elements present. These x-rays are then detected and analyzed to determine the elemental composition of the sample.

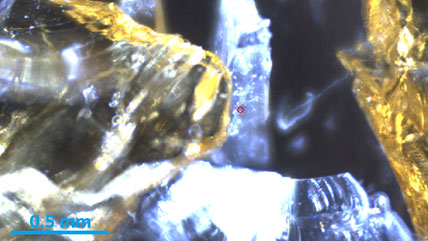

Unlike traditional XRF, micro-XRF uses polycapillary optics or collimators to focus the beam to a small spot, typically in the range of 10 – 50 µm, allowing for localized analysis and high-resolution elemental mapping. This makes it especially useful for heterogeneous or layered samples.

Micro-XRF systems often include motorized stages for scanning, advanced detectors for improved sensitivity, and software for generating elemental distribution maps and quantitative data.

Visit EDAX.com for more information on micro-XRF instrumentation and applications.

Advantages of micro-XRF

Micro-XRF combines the benefits of traditional XRF with spatial resolution, enabling detailed analysis of small features, inclusions, or layered structures. It is particularly valuable for non-destructive testing and analysis of valuable or sensitive samples.

| Capability | Advantage |

|---|---|

| High spatial resolution | Enables localized analysis of small features, inclusions, or defects |

| Non-destructive analysis | Ideal for valuable, historical, or delicate samples |

| Broad elemental range | Detects elements from C – Am |

| Minimal sample prep | Works with solid, powdered, liquid, irregular, or nonconductive samples without extensive preparation |

| Layered structure analysis | Capable of analyzing coatings, laminates, and multi-layered materials |

Workflow for micro-XRF

|

|

Step 1: Sample preparation Minimal preparation is required. Samples can be solid, powdered, liquid, or irregular. Flatness is preferred for optimal focus, but not mandatory. Non-conductive samples do not require coating. |

|

|

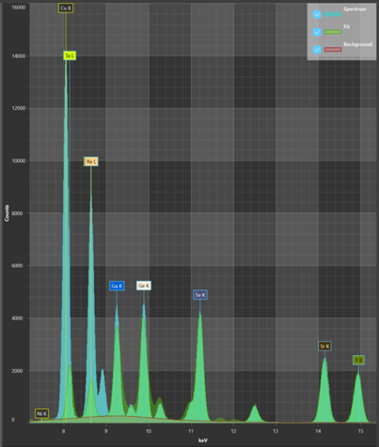

Step 2: Data collection The focused x-ray beam scans the sample surface. Fluorescent x-rays are collected by energy dispersive detectors. The system records the intensity and energy of emitted x-rays to identify and quantify elements. The EDAX® Orbis™ II has a patent orbital turret that precisely targets specific regions, eliminating x-ray interference from adjacent areas and give you the most accurate data. Visit edax.com for more information on the Orbis II micro-XRF system. |

|

|

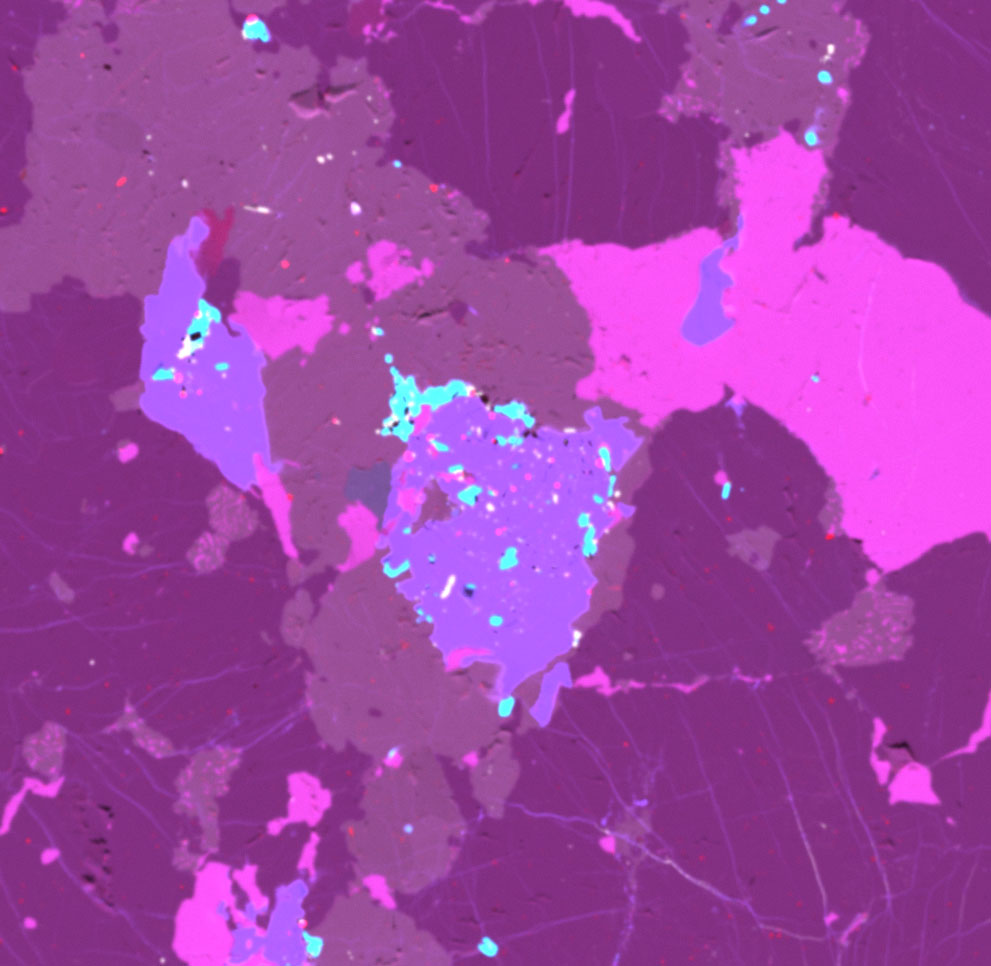

Step 3: Analyze Software generates elemental maps, line scans, and quantitative reports. Users can visualize elemental distributions, detect trace elements, and analyze layered structures. The EDAX Orbis Vision II software streamlines the interface and enables users to perform imaging, elemental analysis, mapping, quantification, and report generation. Visit edax.com for more information on WDS analysis software. |