Continuous electron diffraction tomography, microcrystal electron diffraction (MicroED), or three-dimensional electron diffraction (3DED) is a powerful structural biology and materials science technique that combines transmission electron microscopy (TEM) with electron diffraction to elucidate the atomic-level structure of nanoscale crystals. In this method, a finely focused electron beam captures diffraction patterns from small crystals (<500 nm) while the specimen continuously rotates to enable the determination of their three-dimensional structures.

Key advantages of MicroED/3DED

One of the major advantages of MicroED/3DED is to study samples that are difficult or impossible to analyze by traditional x-ray crystallography methods due to crystal size limitations. You can perform MicroED/3DED on smaller crystals (<500 nm), which can be more readily obtained from challenging samples such as membrane proteins. Although synchrotron x-ray free-electron lasers (XFELs) can be used for small crystals (>500 nm), they require a large number of small crystals, sometimes in the hundreds or thousands, to determine the structure of a single protein or small molecule, making the technique tedious and expensive. In comparison, MicroED/3DED offers a fast, high-resolution analysis that requires only a few small-size crystals.

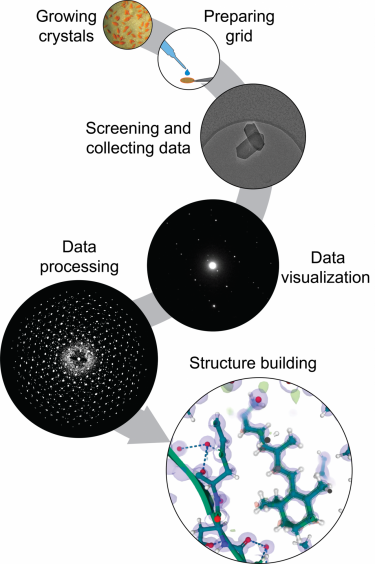

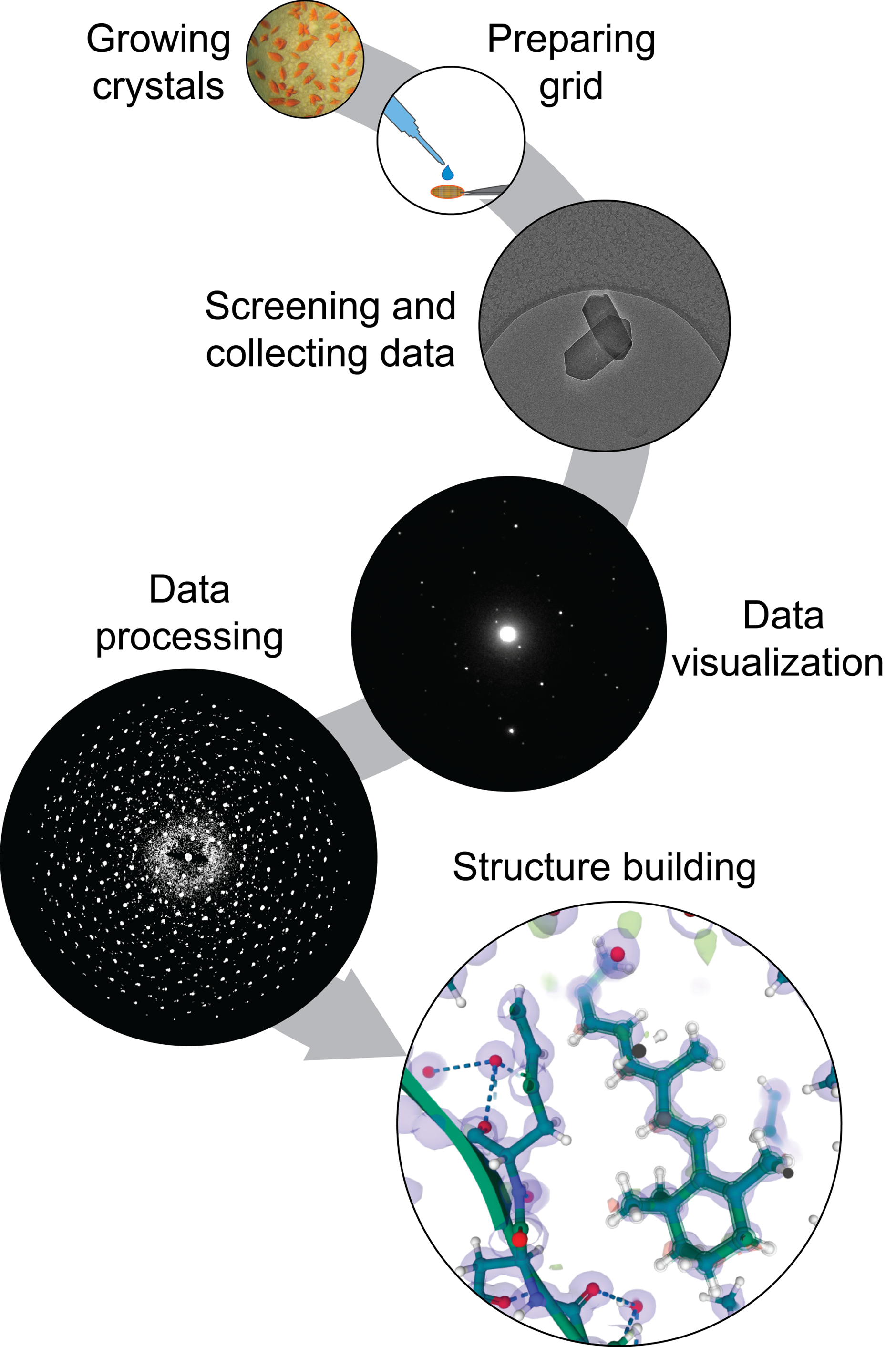

MicroED/3DED workflow

- Grow crystals: Prepare a thin crystal sample of interest. Crystals should be <500 nm thick and transparent to electrons.

- Prepare grid: Apply the crystal sample to a TEM grid.

Note: Crystal growth and grid preparation methods can vary drastically depending on the material in hand; cryo-techniques may also be required in some cases.

- Screen and collect data: Identify single thin crystals that exhibit well-diffracting properties, then collect MicroED/3DED data as a continuous movie by rotating the stage while exposing the crystal to the electron beam.

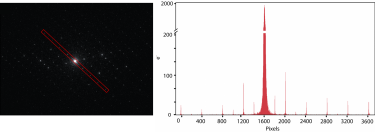

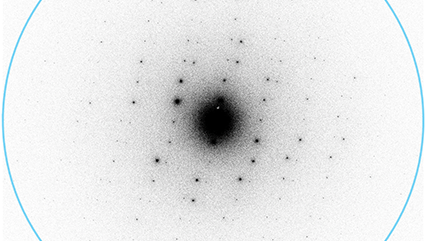

- Visualize data: Extract and visualize each frame from the continuous rotation diffraction data to ensure the well-diffracting properties of the crystal.

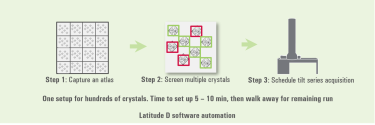

Note: For automated and high-throughput MicroED/3DED data collection, use Latitude® D software.

- Process data: Employ established x-ray software to extract, index, integrate, and scale each frame obtained from the continuous rotation diffraction during MicroED/3DED data collection.

- Build structure: Various software packages, such as Coot, Phenix, or SHELX, are available for structure solution and refinement. This process involves fitting atomic models into the electron density map derived from the diffraction data.

MicroED and direct detection electron counting cameras

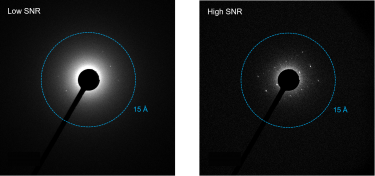

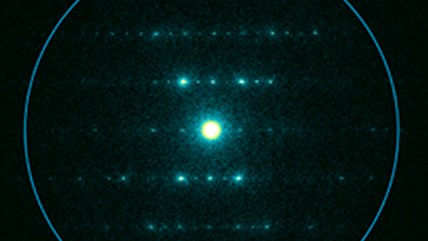

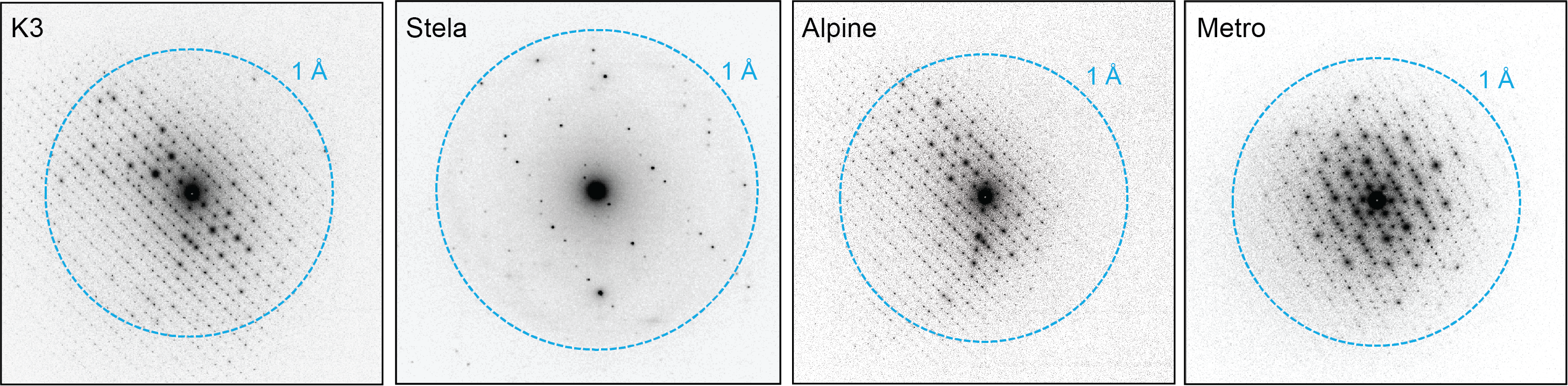

A specimen’s susceptibility to beam-induced damage constrains the electron dose you can use to gather data with MicroED/3DED, thus highlighting the importance of electron counting direct detection cameras. Electron counting significantly improves the signal-to-noise ratio (SNR) and detective quantum efficiency at all spatial frequencies by eliminating signal read noise and variability caused by electron scattering. This ensures accurate measurement of diffraction spot intensities, especially at high-resolution frequencies with lower amplitudes, resulting in high-resolution structure determination at low electron dose.

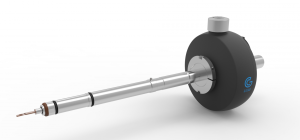

You can perform MicroED/3DED with all current pre- or post-energy filter Gatan cameras, including scintillator-based fiber-coupled cameras (OneView®, ClearView®, and Rio®), as well as direct detection electron counting cameras (K3®, Alpine®, Metro®, and Stela®*). MicroED/3DED data collection with Gatan direct detection electron counting cameras does not require a beam stop (for accurate diffraction focusing and effective data processing). It enables the acquisition of diffraction images with remarkably low background and high SNR for the Bragg intensities that vary over several orders in magnitude (for high-resolution structure determination at extremely low dose conditions).

*Stela utilizes DECTRIS hybrid-pixel technology.