Advantages:

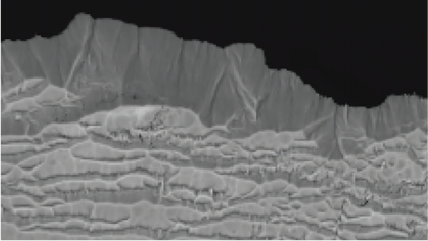

Fully automated argon ion polishing system suitable for preparation of SEM samples to prepare damage free surfaces, cross sections and deposit coatings to protect or eliminate charging.

- Polish, etch or coat samples with a single pump down

- Etch at voltages as low as 100 V for rapid and damage free preparation of sample surfaces

- Permit samples as large as 32 mm in diameter

- Transfer samples from the PECS™ II instrument to a SEM/FIB or glovebox without exposure to air (optional)

- Store and analyze image in DigitalMicrograph® software from Gatan for digital optical imaging

- Display and control all PECS II parameters using integrated 10-inch color touch screen

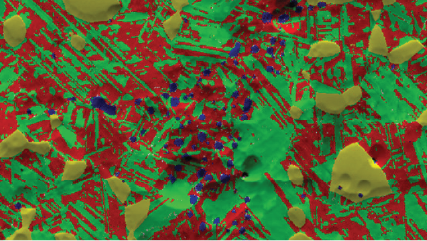

On the role of transmission electron microscopy for precipitation analysis in metallic materials

Critical Reviews in Solid State and Materials Sciences

2021

Journal of Magnesium and Alloys

2021

Materials Science and Engineering: A

2021

Model 685

Datasheet

Applications

Protocols

Cleaning guns and cold cathode gauge

Related products

Cipher® System

DigitalMicrograph Software

Ilion® II System