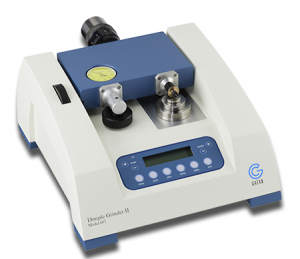

Advantages:

Provides a fast and reliable mechanical method of pre-thinning to near electron transparency to greatly reduce your ion milling times and uneven thinning.

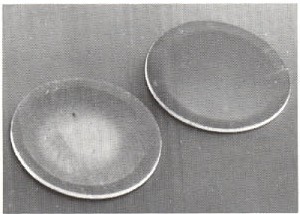

- Large transparent areas: Utilizes both the large wheel and flat wheel to preserve a large transparent area after processing

- Stronger specimens: Leaves a thick supporting rim to protect and strengthen the specimen after dimpling

- Direct preparation of TEM specimens: Produces a final thickness of <3 μm in dimpled specimens

- Accurate depth and thickness control: User-defined stop point and real-time display ensure you can produce the appropriate dimple depth and thickness

- Micro-positioning: Provides both orthogonal and intersect axes for more accurate positioning

Nature Communications

2022